Meet SVR RO

for Rust & Oxidation Turbine Oil

SVR® RO manages fluid chemistry full-time to remove oxidation by-products as they are created, returning the lubricant to a highly unsaturated condition, forcing existing varnish deposits to be dissolved back into the lubricant.

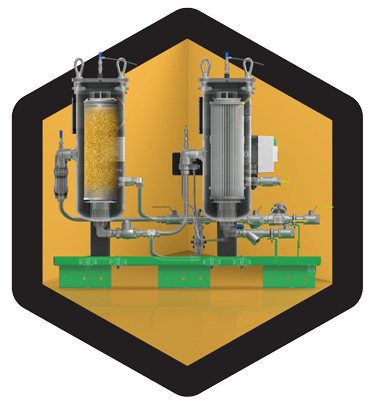

Meet SVR FRF

for Phosphate Ester Fluid

SVR® FRF addresses phosphate ester fluid chemistry, providing 200-400% more filtration capacity than most OEM systems to mitigate high acid levels, gel formation, and rampant varnish, returning fluid quality to operating specifications.

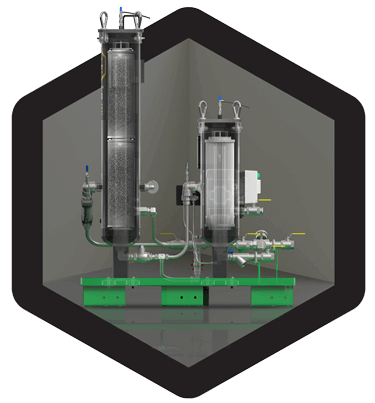

Meet SVR JET

for Aeroderivative Turbine Oil

SVR® JET continuously removes varnish, coking pre-cursors and particulate contamination, breaking the lubricant deposit formation cycle, managing the acid number and maintaining the lubricant in ideal operating conditions.

Meet SVR AW

for Anti-Wear Hydraulic Oil

SVR® AW works 24/7 during hydraulic system operation to remove both dissolved varnish pre-cursors and varnish particles as it is generated to prevent the accumulation of varnish and eliminate the root cause of oil varnishing.

The SVR is a chemistry solution for a chemistry problem™, tested and proven worldwide on 1,803 critical assets.

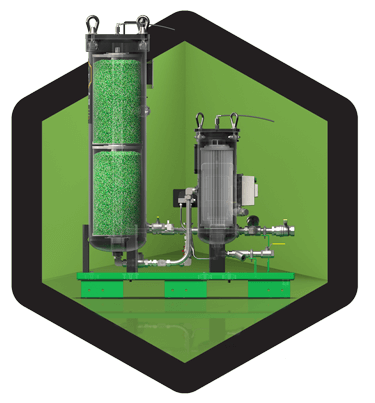

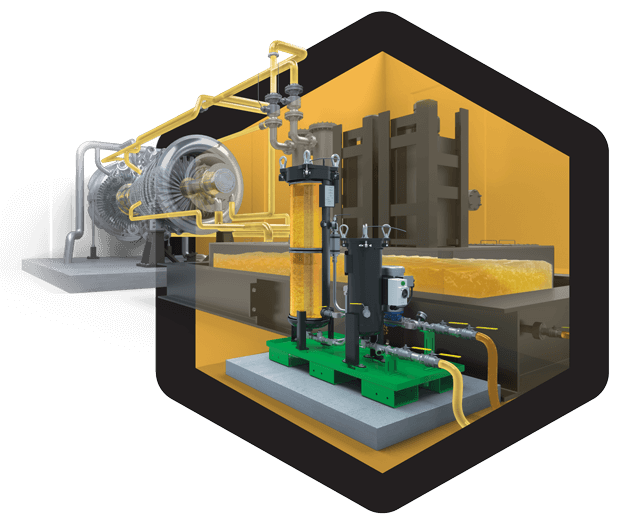

SVR Oil Varnish Removal System

Our engineered dialysis-style oil varnish removal system, SVR®, offers best-in-class mechanical engineering to ISO 9001 standards, chemistry management and solid contamination removal solutions. Tested and proven worldwide on 1,803 critical assets, SVR provides a step-change in lubricant lifecycle management with low maintenance demands outside of routine filter replacement.

The SVR oil varnish removal system restores fluid chemistry full-time, offering the unique advantage of removing harmful contaminants during regular turbine operation when dissolved in the oil. As a result, saturation cannot occur under any lubricant condition, preventing varnish formation.

Utilizing patented ion-exchange technology, ICB®, the SVR oil varnish removal system eliminates chemical breakdown products and varnish at the molecular level, restoring normal demulsibility values and MPC varnish potential values, and reducing Acid Number, maintaining optimal lubricant quality. Through full-time, continuous treatment, SVR stops the contamination cycle in its tracks, cleaning the lubricant every time it cycles through the dialysis circuit. Lubricant life is extended by removing and preventing chemical breakdown material accumulation, mitigating mechanical failures and costly production losses.

Manage Unmanaged Chemical Breakdown Of Turbine And Compressor Lubricants

As the gold standard in turbine lube oil and phosphate ester fluid maintenance, the SVR oil varnish removal system is designed to facilitate rapid deployment without downtime. Just install and reap the following rewards:

- Acid removal

- Varnish prevention

- Additive life extension

- Demulsibility correction

- Mitigate the risk of servo valve sticking

- Remove bearing deposits

- Significantly reduce solid contamination

- Significantly improve fluid resistivity

- Extend lubricant life

- Manufactured to ISO 9001 standards

Supported by a team of world experts and locally trained partners, we work hard to ensure your SVR oil varnish removal system installation is a success. Join the installation movement and protect your critical assets with an industry-leading defense shield.

Transforming Lubricants While They Work As Easy As Turning The SVR On And Letting It Run

The SVR varnish removal system is an all-in-one solution that manages chemistry and solid contamination, ideal for cleaning and maintaining a variety of fluids, including phosphate ester fluids, gas turbine lube oils, steam turbine lube oils and hydraulic oils.

Once the SVR lubricant conditioning system is connected, the lubricant enters a restoration phase. The varnish potential value will go up and down as the contamination deposited on surfaces throughout the system is dissolved back into the oil. While the varnish potential value remains above target, much of the risk to the turbine has been removed as the oil is no longer saturated with dissolved breakdown products. The clean lubricant will actively remove deposits from the system’s mechanical surfaces via chemical equilibrium. When the MPC is reduced to the level demanded (<15), the lubricant is said to enter the stability phase.

Operating turbine lubricants in the stability phase is the goal of each lubricant maintenance program. Lubricant performance will be maximized while operating in this phase, and the risk of a varnish-related failure is extremely low.