You Can’t Manage What You’re Blind To

Life and Death for Lubricants

Lubricants don’t die suddenly. In fact, they usually only die after relatively long periods of neglect. The challenge is that few oil-related problems arise in the first half of a lubricant’s life, making it easy to turn a blind eye to the gradual degradation during their service. Eventually, however, the consequences of unmanaged fluid breakdown surface. The typical results: increased MPC varnish potentials, antioxidant additive depletion and accumulated oxidation material that deposits on equipment surfaces.

But lubricant death is not inevitable. Suppose we consider the root cause of lubricant failure and adjust our maintenance practices to slow down or manage that process. In that case, lubricant aging can be stopped in its tracks, keeping oils healthy and extending their lives significantly. This approach allows for more reliable, sustainable and profitable operations; it’s simply a better way of doing things.

Measure Your Oil’s Vitals

If you want an indication of your health, you’ll probably run tests to check your vital signs. If you want to know how your oil is doing, you’ve got to do likewise. Lubricants may not have a pulse, but oil analysis provides the info that you need about their health. By testing your oil and comparing your results to established limits, you can get a good picture of your fluid’s overall condition and remaining lifetime.

Each oil test method gives you different information that will help you to “triage” your lubricant by answering four critical questions.

1. Will this oil do its job?

To answer this question, look at the oil’s physical properties. Of these, viscosity is by far the most critical. If viscosity is off spec (± 10% of the analogous new oil’s level), the fluid may be dead and probably needs to be changed STAT. If your viscosity is too low, your fluid is too runny and insufficient lubrication can lead to metal-on-metal contact, grinding bearings to a halt. If your viscosity is too high, your fluid is thick and viscous, resulting in poor lubrication and excess friction, heat and energy losses. What good is a lubricant that can’t lubricate?

2. Could an immediate failure occur?

To answer this question, look at your fluid’s contaminant levels, including particles, water and metals.

Particles

Insoluble abrasives result in equipment wear and can ultimately lead to failure. If you have a system with tight clearances, particles can plug them, leading to oil starvation (and failure). Similarly, oil filters can plug and can starve oil systems downstream.

Oil particle levels are generally measured using ISO particle counts. When it comes to these, the limits vary by application. In general, lower particle counts are better, but the following are the lines you don’t want to cross (ie: be above):

Particle Count Limits

- 18/16/13 for steam or gas turbine lube oil applications (ASTM D4378)

- 16/14/11 for EHC fluids and steam turbine oils for hydraulic applications (ASTM D8323)

Water

Simply put: oil and water don’t mix. If you get water into your system, the consequences can be severe, including wear, corrosion, oil breakdown and failure. Water content is usually reported in ppm or %. To avoid issues and keep your oil in shape, you’ll want to maintain water levels as below:

Water Limits

- 200 ppm (0.02%) max for steam or gas turbine lube oil applications (ASTM D4378)

- Above 200 ppm, free water will be present.

- 1,000 ppm (0.1%) max for EHC fluids (ASTM D8323)

- EHC fluid water limits are higher because ester-based oils are hygroscopic and accommodate more moisture without forming free water layers. It’s harder to keep them dry, but you want to do your best because esters react with water (hydrolysis). This reaction rips base oil molecules apart! If you don’t want your ester-based oil to die, keep it suitably dry.

Metals

Keep an eye out for metals like iron, copper, chromium, nickel, aluminum and titanium (to name a few!), as these are often indicative of abnormal wear in your system and could be the first warning signs of a failure in progress. Other metals like calcium, magnesium, zinc, sodium and potassium can clue you into potential fluid cross-contamination. Regardless of where these metals come from, they are catalysts that accelerate oil breakdown. They also promote deposits, gels, soaps and sludges.

3. Is my oil healthy?

Oxidative breakdown is the number 1 killer of oils and leads to the formation of acids and varnish. If you want to know how your oil is doing, it’s essential to look at its breakdown levels. Ultimately, the breakdown leads to lubricants being condemned, so the importance of the following tests cannot be overstated. In addition to being the leading cause of oil death, breakdown products also wreak havoc on your equipment’s performance and reliability. Ultimately, our machines are only as healthy as the oils inside them!

Acid Number (AN)

Acids are corrosive breakdown products that can eat away at the metal surfaces in your system. They’re also varnish precursors that promote deposit formation. Finally, acids are catalysts that accelerate further oil breakdown. Healthy used oils should possess acid levels similar to those they possessed when they were new. If acids levels are creeping up, your oil is in trouble.

- As a rule of thumb, the AN of steam or gas turbine lube oils should not be allowed to double the analogous new oil AN.

- For EHC fluids, 0.20 mg KOH/g is the maximum allowable in-service AN (ASTM D8323). Beyond this threshold, rapid auto-catalytic oil breakdown occurs.

MPC Varnish Potential (ΔE)

Varnish results from unmanaged oil breakdown and is the most common cause of oil-related downtime in gas turbine applications. Despite its prevalence in GTs, varnish impacts steam turbines, compressors and hydraulic systems. By the time it forms, your oil is in critical condition.

An oil’s varnish potential is measured using membrane patch colorimetry (MPC) as outlined by ASTM D7843. Essentially, it’s a patch test that captures varnish and other oil breakdown products on a 0.45-micron filter. Thanks to an essential 72-hour prep process, MPC allows us to see varnish currently dissolved in oils in addition to varnish, which has already become insoluble. Since soluble and insoluble varnish seriously impacts reliability, the MPC test’s ability to measure both is key.

Some labs don’t love 72+ hour-long tests and choose to modify their MPC methods. Unfortunately, this can lead to questionable results, including false positives and negatives, impairing decision-making and resource allocation. Since varnish levels are directly tied to oil life and equipment reliability, EPT Clean Oil recommends only partnering with labs that report the 72-hour MPC hold time as required.

Labs generally set their own MPC ΔE limits. Since this test evaluates an oil’s potential to form harmful varnish, the best target for MPC ΔE should be as close to zero as possible. So long as the oil has a varnish potential, the risk of oil-related issues is real.

4. How long will my oil last?

If your oil was within the required limits for the first three questions above, it’s relatively healthy. The next question becomes: how long will it stay that way? To answer this, you must look at the oil’s remaining lifetime and ensure that its antioxidant additive levels are sufficient to provide the intended protection during continued service. Without antioxidants, oils are defenseless against their number 1 killer: oxidation.

There are two standard tests to evaluate the remaining oil lifetime, providing direct or indirect measurements of antioxidant levels. LSV (sometimes referred to as RULER) directly measures antioxidant levels in %; the higher these are, the longer the oil should last (in theory). By contrast, the RPVOT test degrades the oil, measuring how long it takes to oxidize. This gives a more direct measurement of the remaining oil lifetime and offers an indirect window into the oil’s remaining antioxidant levels.

Regardless of which test you choose to run, their limits are aligned. Indeed, both RPVOT and LSV set 25% virgin oil levels as their limits. So, for RPVOT, that means if your virgin oil took 1,000 minutes to degrade, your oil should be considered dead (or nearly so) when its RPVOT result is 250 minutes. Similarly, new oils start with 100% LSV antioxidant (amine and/or phenol) levels. When this value drops to 25% or lower, your oil’s end is at hand.

Get Your Oil Checked Up Regularly

While the above oil analyses are essential, they’ll only help you manage your oil’s lifecycle if you often perform the recommended testing. Anything less than quarterly testing, and you’ll be largely blind to your oil’s current health. Beware: varnish can rapidly increase in only 1 month, so regular monitoring is key to avoiding problems.

You Get What You Pay For

Oil analysis labs typically offer various test packages at different price points. While saving a few bucks on your oil analysis is tempting, this isn’t a wise choice for critical assets like gas and steam turbines. That $20/month oil analysis package won’t look so good if it causes you to be blind to a problem that leads to an $80 million-dollar failure. Ensure that your oil test package contains, at a minimum, the test methods discussed above!

Establishing proper oil analysis within your maintenance program is some of the best money you can spend since you’ll be assured that you’re running the correct analysis at the right time with the know-how to interpret the resulting data. This provides compelling predictive information essential for lubricant lifecycle management while allowing you to ensure that your critical production asset performs reliably. Remember, you can’t manage what you’re blind to.

Know Where to Turn for More Information

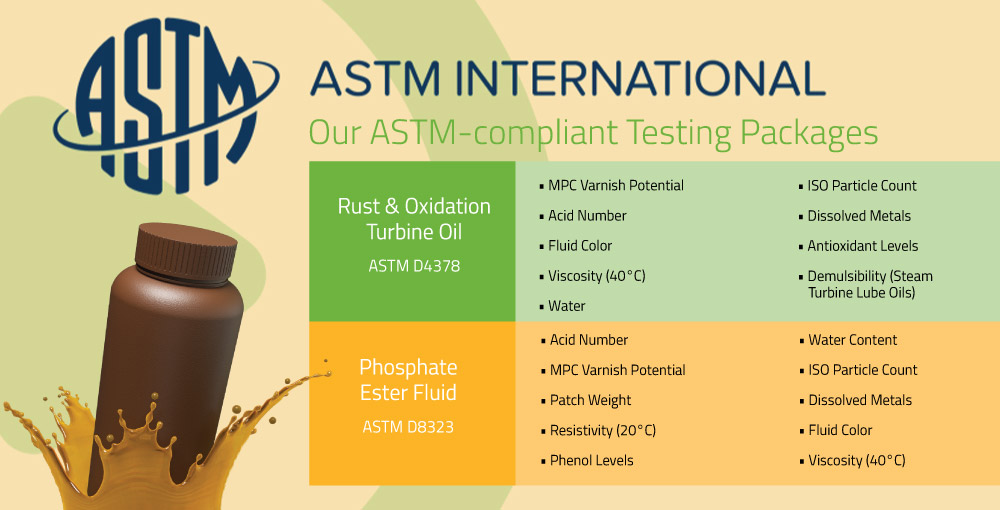

ASTM has developed standards to help end users understand what tests they should perform and how to interpret their test results. For R&O lubricants in Gas and Steam turbines and Combined Cycle applications, ASTM D4378 is the standard guide. ASTM D8323 is your go-to standard for more information on phosphate ester-based Steam Turbine control oils. With resources like these readily available, the tools are at your fingertips to assess if existing oil analysis programs are correct if lubricant health and properties conform to international standards, where the gaps exist and what, if any, actions are required.

Start your journey forward with one of our ASTM-compliant test packages.