What Routine EHC Fluid Analysis Fails to Detect: Improved Phosphate Ester Maintenance Through Non-Routine Testing Technical Paper

Phosphate Ester Fluid 101

Despite the excellent lubricating and safety properties of a phosphate ester fluid, outdated or incomplete Electro-Hydraulic Control (EHC) fluid maintenance is a common problem in the power generation industry that is costing 100s of millions of dollars each year in unnecessary failures and lost production.

Common issues that significantly impair asset reliability, and increase phosphate ester fluid maintenance range from limitations in standard testing capability to conventional EHC fluid maintenance products and procedures.

At EPT Clean Oil our 4-step approach is comprehensive in scope, targets common weaknesses, and removes the contamination responsible for unnecessary failures, while reducing maintenance costs.

Step 1: Improve fluid testing with our ACE™ Assessment aligned with ASTM D8323 standards for in-service phosphate ester fluids

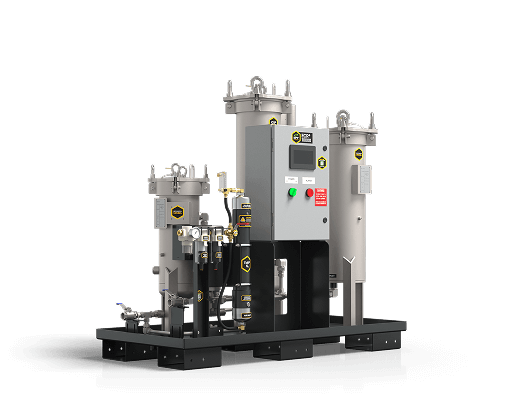

Step 2: Remove acids and dissolved contamination with ICB® Filters

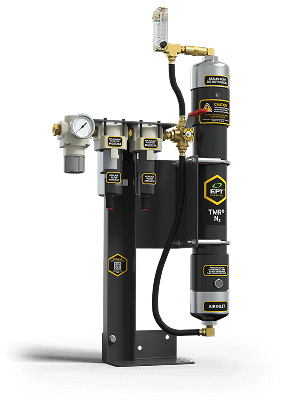

Step 3: Remove water with the TMR® N2 System

Step 4: Remove particulate contamination with the ECR® System

What are phosphate ester fluids?

Phosphate ester fluids are specialized synthetic lubricants that have unique fire-resistant and self-extinguishing properties. Their chemistry does not allow enough energy or vapor to be produced for them to sustain a flame and is the reason that they are the fluid of choice in Electro-Hydraulic control (EHC) systems.

Why are phosphate ester fluids used?

In the case of steam turbine EHC systems, the close proximity of high-pressure hydraulic systems to high-temperature steam manifolds etc. makes the use of fire-resistant fluids (FRFs) essential to ensure the integrity of the turbine and the safety of personnel.

What are the biggest issues with phosphate ester FRFs?

These fluids can be challenging to maintain when inadequate filtration systems are used. They degrade by multiple pathways (hydrolysis, oxidation etc.) which produce harmful breakdown products (acids, varnish etc.). Appropriate fluid maintenance, testing, and chemistry management are therefore essential when phosphate esters are used. They are also expensive, costing upwards of $7000/drum, providing an economic incentive to properly maintain them, lest they need to be replaced.

What are the primary contamination pathways for phosphate ester fluids?

The primary contaminants in phosphate ester fluids are acids, varnish, phenols, dissolved metals, water and solids. These fluids break down to generate acids much quicker than conventional turbine lubricants; moreover, phosphate esters can also produce more harmful strong acids which can catalyze additional, rapid degradation. Contaminant levels must, therefore, be carefully monitored.

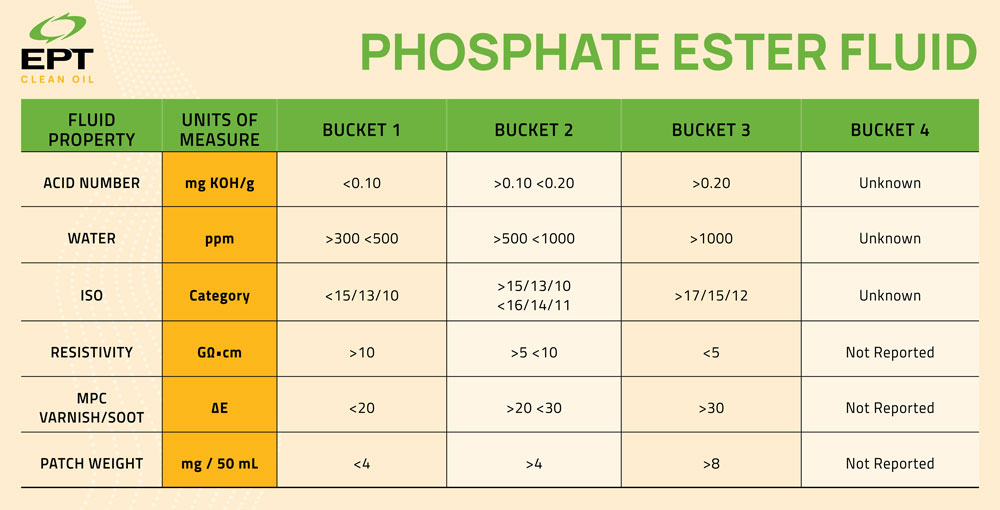

What is the fluid condemning limit in regards to the acid number of a phosphate ester fluid?

New phosphate esters typically have acid numbers < 0.05 mg KOH/g. During service, a phosphate ester’s target acid number should always be < 0.10 mg KOH/g. The upper, or condemning, limit, is 0.20 mg KOH/g. If you are above this level, you are operating outside of specification and at significant risk of EHC system failure; immediate action is, therefore, required.

What tests are required to properly monitor phosphate ester FRFs?

Routine FRF analysis is often limited to acid number, water content, resistivity, viscosity and particle counting. This is insufficient for phosphate esters. The ASTM standard for in-service phosphate ester FRFs is ASTM D8323. This standard requires 9 fluid properties, including MPC, to be tested on a monthly basis. EPT Clean Oil’s Fluid Technical Center offers comprehensive phosphate ester evaluations to ASTM D8323 standards.

What solutions can be implemented to target phosphate ester FRF contamination?

Acid-removal systems, such as the SVR® FRF backed by ICB® FRF patented ion-exchange technology, are required in EHC applications. Take care to ensure that your acid-removal system can also remove harmful varnish that forms as a natural function of FRF service. Since phosphate esters break down hydrolytically, water removal by TMR® N2 is also advised. Finally, solid contamination must be removed with upgraded high-efficiency filters and ECR® electrostatic filtration (for sub-micron particles which escape even the finest conventional filter).