The Importance of Full-time Lubricant Chemistry Management with SVR® Oil Varnish Removal

In the first video in this series, “ICB® Ion-Exchange Filter Change Intervals Explained“, we explained how to establish effective turbine lubricant maintenance and testing through regimented oil analysis and ICB® ion-exchange filter change intervals. We will now turn to the importance of full-time Lubricant Chemistry Management.

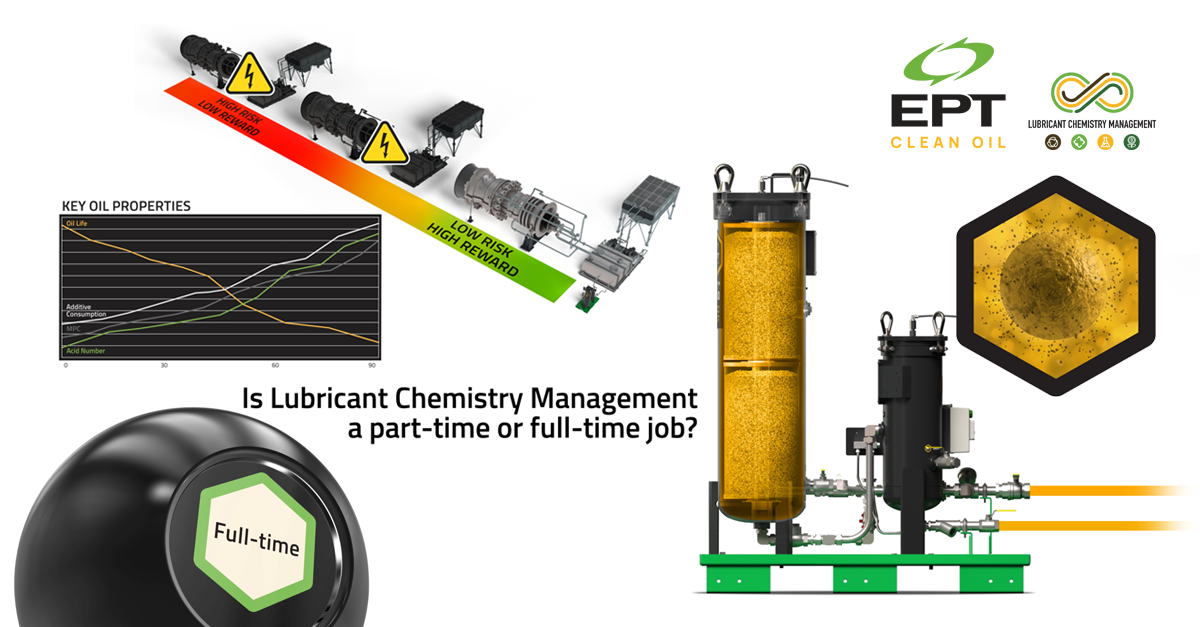

Lubricant Chemistry Management technology, such as the SVR® Oil Varnish Removal System, places a protective shield over your critical assets. Going beyond particulate removal, SVR, backed by patented ICB® ion-exchange technology, actively eliminates chemical breakdown products, including varnish precursors and oxidation materials. When applied full-time, additive consumption is reduced, offering the ability to significantly extend oil life, maintaining ideal oil chemistry for the life of the oil.

In the absence of full-time Lubricant Chemistry Management, quality will regress, and additive consumption will increase, impacting the life of the lubricant. More importantly, unmanaged, it’s not a matter of if, but when varnish will eventually rear its ugly head.

Target the root cause of oil breakdown and take your maintenance program to the next level with full-time Lubricant Chemistry Management and SVR® Oil Varnish Removal.