Proactively manage fluid chemistry and physical contamination to ASTM D8323 standards

Engineered Fluid Contamination Solutions for critical Steam Turbine Electro-Hydraulic Control Systems (EHC Systems)

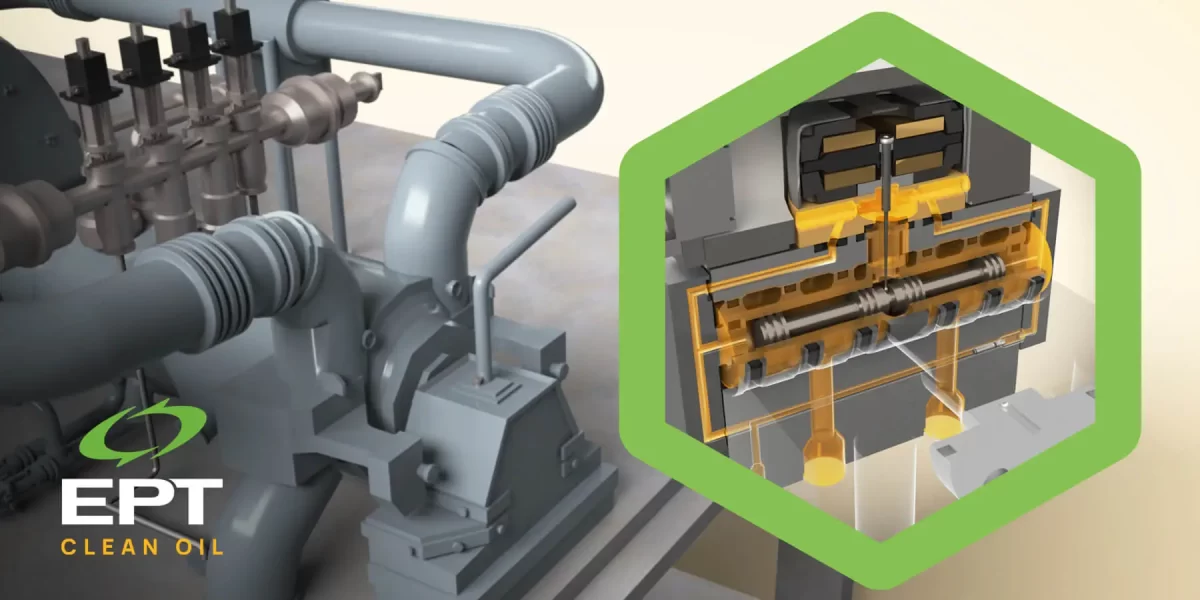

The Electro-Hydraulic Control System (EHC System) is one of the most critical systems controlling steam flow, turbine speed and generator output. The proper functioning and reliable operation of the EHC system is critical and the biggest challenge of O&M Managers and Engineers. Responsible for the reliable and rapid closing of all steam valves including emergency situations such as turbine overspeed and power-load imbalance, a malfunction within the EHC system leads to a domino effect resulting in turbine stoppage.

Lubrication plays a vital role in supporting optimal steam turbine performance. Operating under extreme conditions and high temperature operations, turbine control and protection systems demand specialized synthetic EHC fluids known as fire-resistant fluid (FRF). These fluids offer excellent lubricating properties, however they require strict control as they have a tendency to adsorb water, form acids and produce varnish. FRF fluid degradation results in sticking valves, eroded servo valves, plugged filters and/or blocked servo valve strainers – turbine operation failure mechanisms.

To achieve optimal performance characteristics, fluid chemistry and solid contamination need to be in a managed state. Proactively manage fluid quality to ASTM D8323 standards with EPT Clean Oil’s engineered contamination removal solutions.

Duplex High Pressure Filter System

Proactively manage physical contamination in the duplex high pressure filter system with stainless fiber elements. Upgrading traditional glass media to stainless fiber media eliminates the risk of fiber shedding, protecting servo valve strainers.

Low Pressure Acid Filter System

The low pressure system can be retrofitted with patented ion exchange ICB® filters, engineered to address the fluid chemistry, removing fluid breakdown products, acids, phenols and varnish in the fluid.

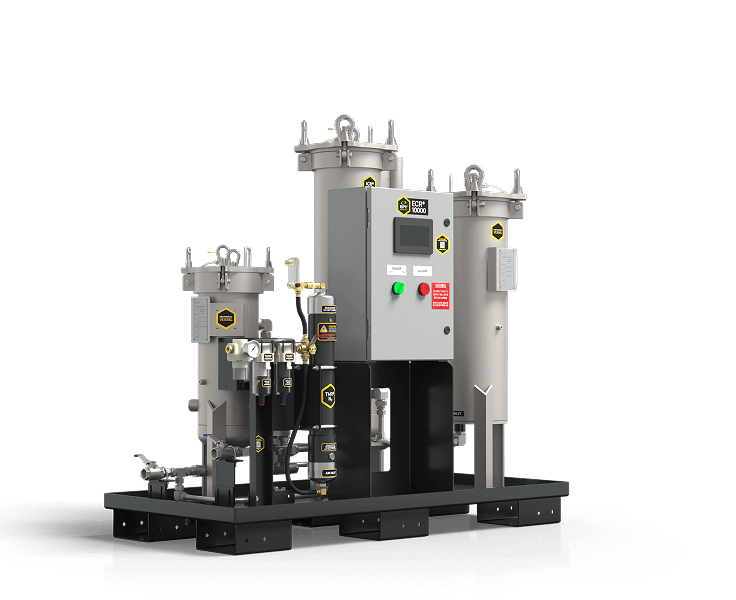

EHC System Sub-Micron Contamination Removal

ECR® is the missing link in proactive fluid maintenance. Using electrostatic fields and proprietary collector elements, the ECR focuses on sub-micron particulate contamination left unaddressed by mechanical filters.

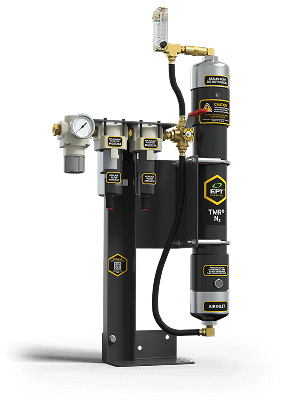

Eliminate EHC System Atmospheric Water Ingression

Ester based lubricants attract atmospheric water, resulting in breakdown and acid formation. TMR® N2 provides the security blanket your reservoir needs, insulating the headspace above the lubricant surface with high purity nitrogen. This eliminates atmospheric water ingression, managing fluid chemistry and factors that accelerate oxidation.

The results speak for themselves:

- Increased duplex filter efficiency and lifespan

- Decreased acid number and increased resistivity

- Steadily decreasing MPC values and improved patch color

- Improved fluid color

- Improved servo valve spool response time

- Constant megawatt production output

Avoid costly and catastrophic consequences. Invest in proactive fluid management with EPT Clean Oil’s engineered contamination removal solutions. Our team of experienced professionals and industry experts are here to support O&M Managers and Engineers optimize preventative maintenance programs and maintain turbine uptime moving forward.