A Breakthrough, Not a Breakdown.

If your turbine could talk, what would it say?

What if the internal monologue of your turbine sounded like this?

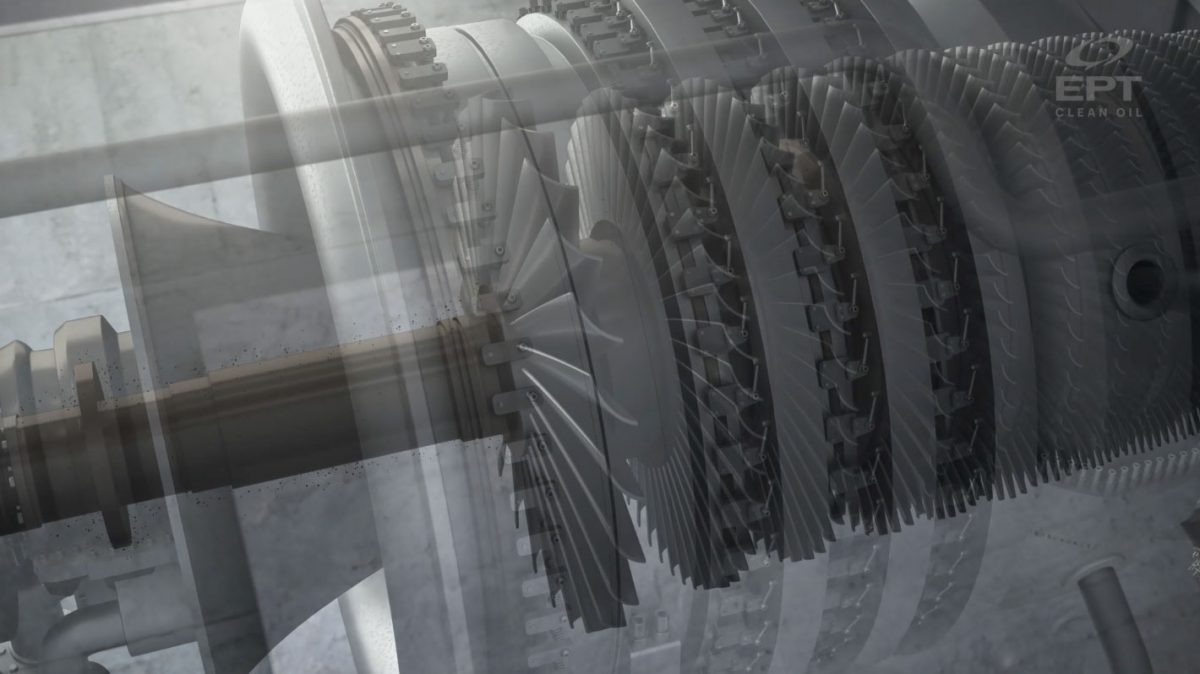

From the first day we are put into service our mission is to continue rotating – period. We are not whole unless we are operating. Our lifeblood – in spec quality lubricant free flowing without varnish.

Over time we age – the lubricant pumping through us, our mechanical components, everything. Our oils’ reserves exhausted. Our daily rotations exhaust us. Life for a turbine not rotating is unnerving. We are out of service. Off the grid.

We need a partner. A partner that understands the importance of lifeblood – of lubricant quality. The importance of seamless performance. The importance of our continuous operation.

~Turbines Everywhere

Your turbine has a story. Take the time to listen.

Through the act of humanizing a turbine, the voiceless can be heard and seen differently. Turbines, like humans, have demands. They demand routine health checks, annual exams, maintenance and monitoring – they demand a partner. In the absence, it is not a matter of if, but when your turbine will be unavailable when it is demanded. And the price you pay is high in the event this occurs.

This is why in 2005, EPT Clean Oil introduced the first generation SVR® Lubricant Conditioning System. We listened, engineering a kidney loop system that works 100% of the time, to target the underlying cause of turbine lubricant failure: chemical breakdown.

Utilizing patented ion-exchange resin technology, ICB®, SVR removes chemical breakdown products and varnish at the molecular level, maintaining optimal lubricant quality. Through full-time, continuous treatment, SVR stops the contamination cycle in its tracks, cleaning the lubricant every time it cycles through the kidney loop circuit. By removing and preventing chemical breakdown material accumulation, lubricant life is extended, mitigating mechanical failures and costly production losses.

The result – your turbine is online, in action, continuously operating.