MPC Varnish Testing: It’s not Just About the Number

Oil Analysis and Testing 101

Understanding your in-service oil’s condition and remaining lifetime with oil analysis and testing is essential to establishing alignment with future maintenance windows and proactive strategies for optimization.

At EPT Clean Oil, we specialize in lubricant analysis for critical rotating equipment and EHC systems. We don’t want to be a jack of all trades; we focus on being the masters of what we do. Each sample sent to the Fluid Technical Center is, therefore, examined uniquely. Our chemists take the time to review and critically analyze your results before outlining our findings. We focus on doing things right and providing the answers that you need.

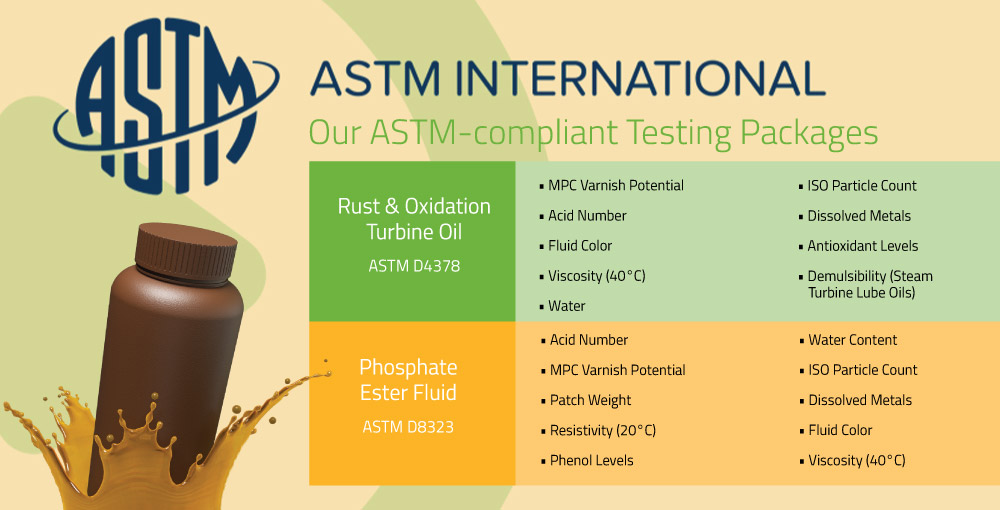

Treat your lubricant like the asset it is and invest in the right test, at the right time, to the right ASTM standard.

When it comes to critical turbine and compressor lubricants, what is the right test?

There is no one right test. Each test method for your oil gives you different information, so it is critical that you are performing the right tests.

What data points are critical?

You want to start by breaking down the oil analysis reports into tests, triaging them, identifying issues which could cause immediate problems in your system, prioritizing them, and then moving on down the list.

What steps are required when prioritizing your oil analysis report?

Step one would be to look at the fluid parameters. If the viscosity is off-spec, that oil needs to be changed. Step two would be looking for contamination like particles and water, while step three addresses oil breakdown products such as varnish and acid. Step four ensures that additive levels are sufficient to provide the intended protection during continued service.

What is the optimal timing or testing interval for these tests?

It’s essential to do the necessary testing regularly and, at the very least, quarterly. Anything less than quarterly and you are not seeing the oil’s actual condition as varnish potentially can increase very quickly. You should pick a test package which shows you all the properties you need to be regularly monitoring on at least a quarterly basis or even monthly for those critical systems.

What are the necessary tests for FRF and R&O lubricants?

ASTM has developed standard guides to help end-users understand what tests they should be performing and help them interpret the results of those tests. For R&O lubricants, ASTM D4378 is the standard guide for in-service monitoring of steam and gas turbines. For your FRFs, the phosphate ester-based control oils in a steam turbine, ASTM D8323, is a beneficial resource.

Is it obvious where limits and targets are listed on an oil analysis?

It can vary significantly with many different labs running different oil analysis packages. It’s important to know what you are getting out of your oil analysis report depending on what lab you are using. EPT Clean Oil’s Fluid Technical Center offers specialized oil analysis and comprehensive evaluations that other labs don’t, resulting in a complete picture of your lubricant’s condition.

What does the EPT Clean Oil Fluid Technical Center offer?

Built from the ground up to be a world-class R&D facility, EPT Clean Oil’s Fluid Technical Center is an in-house oil analysis lab offering specialized oil analysis and comprehensive evaluations on turbine lube oil and hydraulic control fluid. Our testing packages provide in-depth assessment and root cause analysis for your application. The resulting data is reviewed and interpreted by application specialists and Ph.D. chemists, with concluding recommendations delivered in our ACE™ report.

What is our ACE™ assessment all about?

Our ACE™ Oil Analysis assessment goes beyond standard lab analysis to ensure essential information isn’t missed in managing EHC fluids and turbine lubricants. The ACE report highlights potential oil-related issues and then demonstrates the impact EPT Clean Oil technologies would have if employed on-site. To do this, we have developed sophisticated lab-scale versions of our filtration skids, allowing us to clean your oil sample the same way we would clean your oil reservoir. Every in-service oil has different problems. Our approach lets you be confident that the solutions we recommend will work in your application.