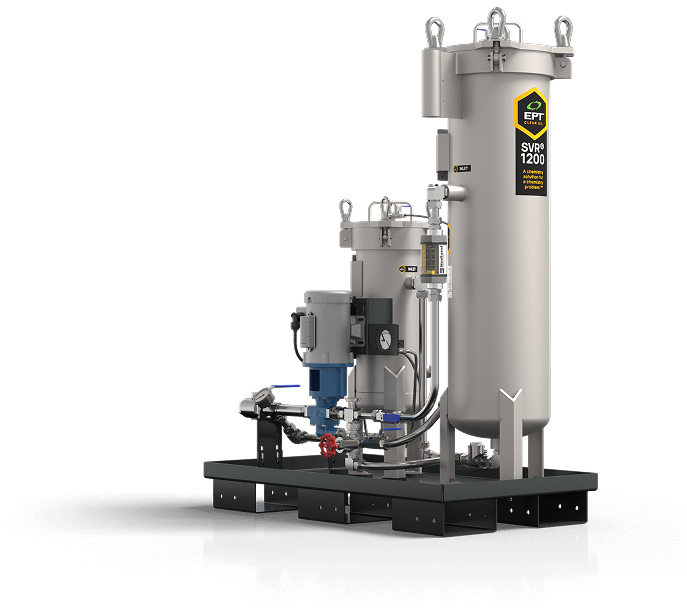

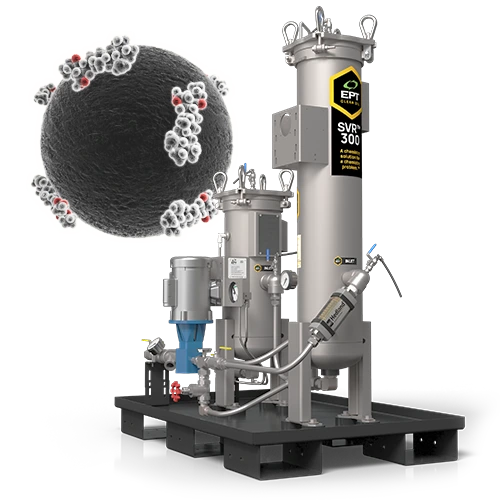

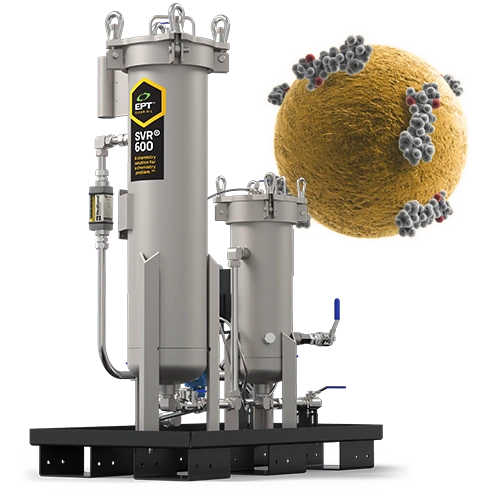

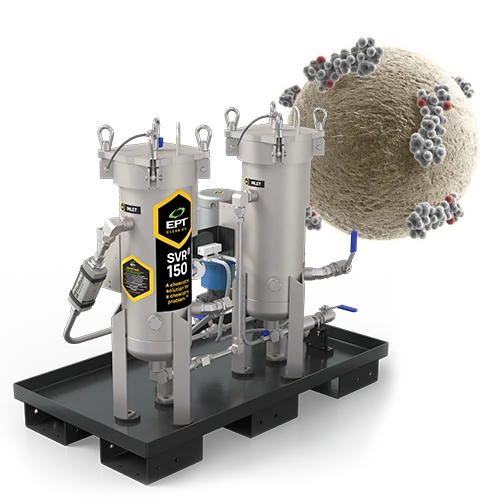

SVR® Oil Varnish Removal System

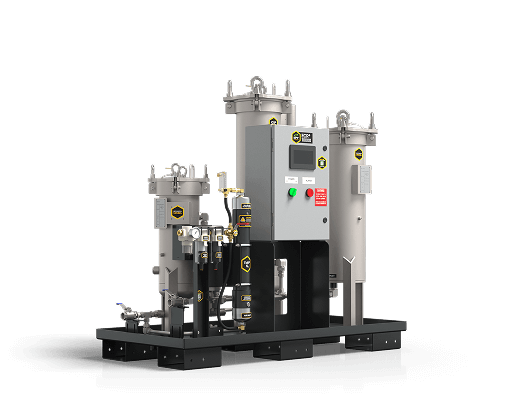

Our dialysis-style oil varnish removal system, SVR®, offers best-in-class manufacturing to ISO 9001 standards, chemistry management and solid contamination removal solutions. Tested and proven worldwide on thousands of critical assets, SVR provides a step-change in lubricant lifecycle management with low maintenance demands outside of routine filter replacement.

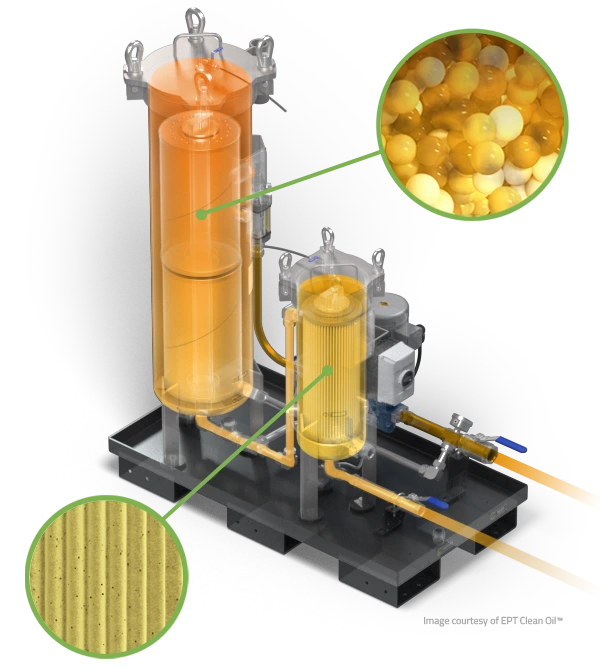

The SVR oil varnish removal system restores fluid chemistry full-time, offering the unique advantage of removing harmful contaminants during regular turbine operation when dissolved in the oil. As a result, saturation cannot occur under any lubricant condition, preventing varnish formation.

Utilizing patented ion-exchange technology, ICB®, the SVR oil varnish removal system eliminates chemical breakdown products and varnish at the molecular level, restoring normal demulsibility values and MPC varnish potential values, and reducing Acid Number, maintaining optimal lubricant quality. Through full-time, continuous treatment, SVR stops the contamination cycle in its tracks, cleaning the lubricant every time it cycles through the dialysis circuit. Lubricant life is extended by removing and preventing chemical breakdown material accumulation, mitigating mechanical failures and costly production losses.

SVR Oil Varnish Removal System Comparison Tool

| SVR® HYDRO | SVR® 150 | SVR® 300 | SVR® 600 | SVR® 1200 | |

|  |  |  |  | |

| Reservoir Volume (Mineral Oil) | Minimum: 2,500 L/ 660 gal Maximum: 15,000 L / 3,963 gal | Minimum: 715 L / 189 gal Maximum: 2,870 L / 758 gal | Minimum: 1,440 L / 380 gal Maximum: 5,740 L / 1,516 gal | Minimum: 3,785 L / 1,000 gal Maximum: 16,278 L / 4,300 gal | Minimum: 5,980 L / 1,579 gal Maximum: 27,255 L / 7,200 gal |

| Reservoir Volume (Synthetic Oil) | Minimum: 240 L / 63 gal Maximum: 960 L / 253 gal | Minimum: 480 L / 126 gal Maximum: 1,912 L / 505 gal | Minimum: 1,435 L / 379 gal Maximum: 5,680 L / 1,500 gal | Minimum: 2,272 L / 600 gal Maximum: 9,085 L / 2,400 gal | |

| ICB Flow Rate | 19.0 lpm / 5.0 gpm | 2.0 lpm / 0.5 gpm | 4.0 lpm / 1.0 gpm | 12.0 lpm / 3.0 gpm | 19.0 lpm / 5.0 gpm |

| System flow rate through high efficiency filtration | 38.61 lpm / 10.2 gpm | 8.0 lpm / 2.1 gpm | 8.0 lpm / 2.1 gpm | 38.61 lpm / 10.2 gpm | 38.61 lpm / 10.2 gpm |

| ICB Filter Model | RO | RO FRF JET AW | JRO FRF JET AW | RO FRF JET AW | RO FRF JET AW |

| Fluid Applications | Rust and oxidation turbine oil only at this time | Rust & Oxidation Turbine Oil (RO) Phosphate Ester Fluid (FRF) Aeroderivative Turbine Oil (JET) Anti-Wear Hydraulic Oil (AW) | Rust & Oxidation Turbine Oil (RO) Phosphate Ester Fluid (FRF) Aeroderivative Turbine Oil (JET) Anti-Wear Hydraulic Oil (AW) | Rust & Oxidation Turbine Oil (RO) Phosphate Ester Fluid (FRF) Aeroderivative Turbine Oil (JET) Anti-Wear Hydraulic Oil (AW) | Rust & Oxidation Turbine Oil (RO) Phosphate Ester Fluid (FRF) Aeroderivative Turbine Oil (JET) Anti-Wear Hydraulic Oil (AW) |

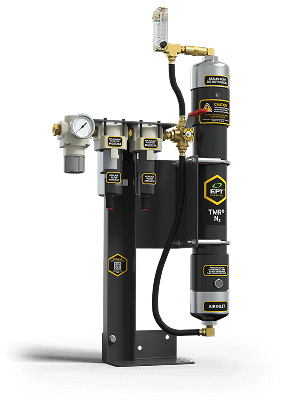

| Other Proprietary Filters and System Requirements | TMR® AquaPurge Coalescer | For synthetic oils, it is advised to combine a TMR® N2 for water removal | For synthetic oils, it is advised to combine a TMR® N2 for water removal | For synthetic oils, it is advised to combine a TMR® N2 for water removal | For synthetic oils, it is advised to combine a TMR® N2 for water removal |

| Contaminant Targets | Soluble Varnish Insoluble Varnish Oxidation by-products Water Particulate removal | Soluble Varnish Insoluble Varnish Particulate removal | Soluble Varnish Insoluble Varnish Particulate removal | Soluble Varnish Insoluble Varnish Particulate removal | Soluble Varnish Insoluble Varnish Particulate removal |

| Electrical Options | General Purpose electrical only at this time | General Purpose with 50 Hz and 60 Hz electrical voltage options CSA Class 1 Div 1 Group C&D with 50 Hz and 60Hz electrical voltage options CSA Class 1 Div 2 Group A, B, C & D with 50 Hz and 60 Hz electrical voltage options IECeX and ATEX-approved configurations are available. Please get in touch with us for more information. | General Purpose with 50 Hz and 60 Hz electrical voltage options CSA Class 1 Div 1 Group C&D with 50 Hz and 60Hz electrical voltage options CSA Class 1 Div 2 Group A, B, C & D with 50 Hz and 60 Hz electrical voltage options IECeX and ATEX-approved configurations are available. Please get in touch with us for more information. | General Purpose with 50 Hz and 60 Hz electrical voltage options CSA Class 1 Div 1 Group C&D with 50 Hz and 60Hz electrical voltage options CSA Class 1 Div 2 Group A, B, C & D with 50 Hz and 60 Hz electrical voltage options IECeX and ATEX-approved configurations are available. Please get in touch with us for more information. | General Purpose with 50 Hz and 60 Hz electrical voltage options CSA Class 1 Div 1 Group C&D with 50 Hz and 60Hz electrical voltage options CSA Class 1 Div 2 Group A, B, C & D with 50 Hz and 60 Hz electrical voltage options IECeX and ATEX-approved configurations are available. Please get in touch with us for more information. |

Manage Unmanaged Chemical Breakdown Of Turbine And Compressor Lubricants

As the gold standard in turbine lube oil and phosphate ester fluid maintenance, the SVR oil varnish removal system is designed to facilitate rapid deployment without downtime. Just install and reap the following rewards:

- Acid removal

- Varnish prevention

- Additive life extension

- Demulsibility correction

- Mitigate the risk of servo valve sticking

- Remove bearing deposits

- Significantly reduce solid contamination

- Significantly improve fluid resistivity

- Extend lubricant life

- Manufactured to ISO 9001 standards

Supported by a team of world experts and locally trained partners, we work hard to ensure your SVR oil varnish removal system installation is a success. Join the installation movement and protect your critical assets with an industry-leading defence shield.

CASE STUDY

Acid number and MPC varnish potential improved by 78% and 90%, respectively, after installing an SVR® backed by patented ICB® ion exchange technology. Since the LM 6000 has not experienced problems relating to oil breakdown.

CASE STUDY

This proven case study, backed by over 10 years of success, explores how installing an SVR® on day one significantly impacted lubricant quality, with lubricant quality after 10 years like new.

Meet SVR® Oil Varnish Removal System

WatchTransforming Lubricants While They Work As Easy As Turning The SVR On And Letting It Run

The SVR oil varnish removal system is an all-in-one solution that manages chemistry and solid contamination, ideal for cleaning and maintaining a variety of fluids, including phosphate ester fluids, gas turbine lube oils, steam turbine lube oils and hydraulic oils.

Once the SVR oil varnish removal system is connected, the lubricant enters a restoration phase. The varnish potential value will go up and down as the contamination deposited on surfaces throughout the system is dissolved back into the oil. While the varnish potential value remains above target, much of the risk to the turbine has been removed as the oil is no longer saturated with dissolved breakdown products. The clean lubricant will actively remove deposits from the system’s mechanical surfaces via chemical equilibrium. When the MPC is reduced to the level demanded (<15), the lubricant is said to enter the stability phase.

Operating turbine lubricants in the stability phase is the goal of each lubricant maintenance program. Lubricant performance will be maximized while operating in this phase, and the risk of a varnish-related failure is extremely low.

What Pain Does the SVR Solve?

Watch

Meet SVR RO

for Rust & Oxidation Turbine Oil

SVR® RO manages fluid chemistry full-time to remove oxidation by-products as they are created, returning the lubricant to a highly unsaturated condition, forcing existing varnish deposits to be dissolved back into the lubricant.

Meet SVR JET

for Aeroderivative Turbine Oil

SVR® JET continuously removes varnish, coking pre-cursors and particulate contamination, breaking the lubricant deposit formation cycle, managing the acid number and maintaining the lubricant in ideal operating conditions.

Meet SVR FRF

for Phosphate Ester Fluid

SVR® FRF addresses phosphate ester fluid chemistry, providing 200-400% more filtration capacity than most OEM systems to mitigate high acid levels, gel formation, and rampant varnish, returning fluid quality to operating specifications.

Meet SVR AW

for Anti-Wear Hydraulic Oil

SVR® AW works 24/7 during hydraulic system operation to remove dissolved varnish precursors and particles as they are generated, preventing varnish accumulation and eliminating the root cause of oil varnishing in anti-wear hydraulic oil.

Make Informed Decisions with our ACE™ Oil Analysis

Submit an oil sample today to get a comprehensive, ASTM compliant understanding of your in-service oil’s condition and remaining lifetime so that it can be aligned with future maintenance windows and proactive strategies for optimization.