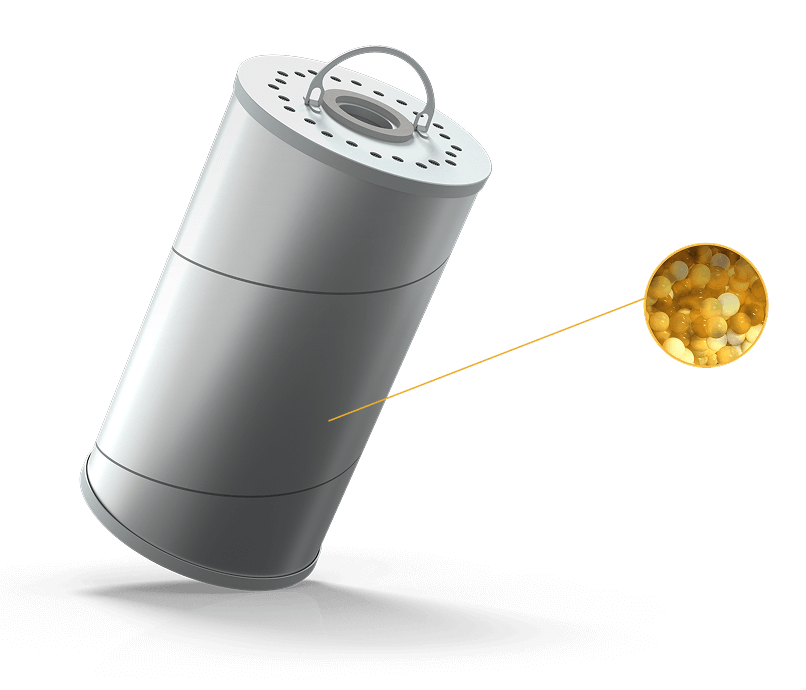

Patented ICB Ion- Exchange Filter

With thousands of installations worldwide and documented contaminant-removal results, our patented ICB® ion-exchange filter combines best-in-class chemistry and materials to deliver the most robust filter available since 1992.

EPT Clean Oil’s patented ICB ion-exchange filter is specifically designed to eliminate dissolved oxidation molecules that can accumulate and cause mechanical issues in bearings, seals, and servo valves. These filters are highly effective, significantly improving oil performance and ensuring system reliability and production. They provide benefits that extend beyond simple acid and particle removal.

Originally developed in 1992 for phosphate ester fluids, EPT Clean Oil has since expanded the capabilities of ICB ion-exchange filters to accommodate a diverse range of lubricants and fluids. This includes Rust and Oxidation Turbine Oil, Phosphate Ester Fluid, Aeroderivative Turbine Oil, and Anti-Wear Hydraulic Oil.

Meet ICB Ion-Exchange Filter

WatchOften imitated. Never duplicated. Patented ICB ion-exchange filter.

Rust & Oxidation Turbine Oil

Rust- and oxidation-inhibited oils, also known as R&O Oils or Turbine oils, are designed for use in turbines, compressors, and other rotating applications. These lubricants break down due to oxidation, creating dissolved contaminants that accumulate until they saturate the oil, forming varnish.

Phosphate Ester Fluid

Phosphate esters are fire-resistant fluids (FRFs) used in turbine electro-hydraulic control (EHC) systems throughout the power generation industry. Used primarily for their fire-resistant properties and thermal stability, these synthetic fluids hydrolyze and oxidize readily during service, creating harmful acids and phenols.

Aeroderivative Turbine Oil

Aeroderivative turbine oil, made from high-quality polyol ester base stocks, offers high oxidative stability and unique viscosity requirements. These oils break down due to oxidation and hydrolysis, creating dissolved degradation products. Once the lubricant becomes saturated with dissolved breakdown products, varnish and coking deposits form.

Anti-Wear Hydraulic Oil

Anti-wear (AW) hydraulic oils are found in various applications, from small assembly processes to integrated steel and paper mill applications. Offering excellent protection against corrosive acid and metal surface wear in critical hydraulic systems, Anti-wear hydraulic oils break down to form varnish due to oxidation of their base oil and additive depletion.

- Removes the underlying cause of varnish and existing deposits by restoring fluid solubility, shifting chemical equilibrium back towards the original fluid condition, eliminating millions of liters of lubricant waste annually.

- 100% effective under normal turbine operating conditions when varnish tends to be dissolved in the oil, creating stability within lubrication and fluid systems, mitigating the risk of premature deterioration.

- Prevents millions of dollars-worth of avoidable losses over a turbine’s lifetime and eliminates oil-related downtime.

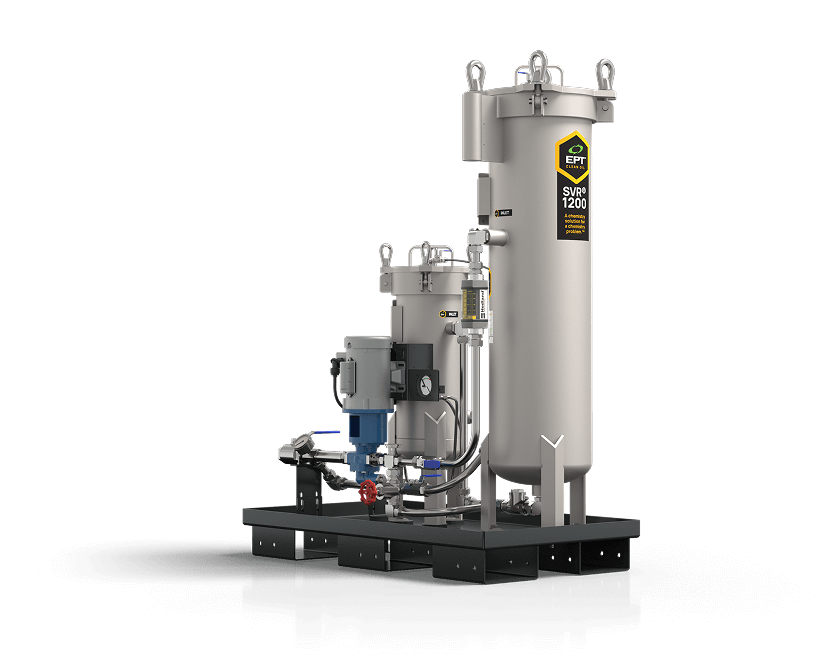

Meet the Ideal Match for ICB Ion- Exchange Filter

SVR® for Varnish Removal

From the moment lubricants are put into service, they chemically break down. The primary pathway: oxidation. The result: oxidation products that dissolve in the oil. All too often, this dissolved oxidation material goes unmanaged by routine maintenance.

Modern turbine and compressor oils are non-polar, and oxidation material is polar, resulting in a tendency for this oxidation material to be more attracted to metal surfaces than the oil itself—the result: deposits on mechanical surfaces including bearings and valves.

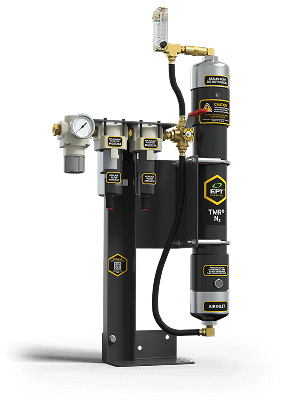

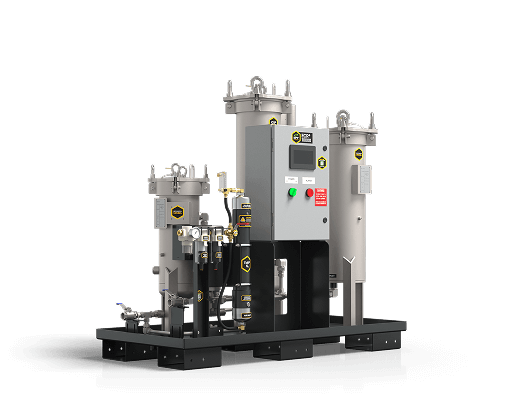

SVR® is an engineered lubricant conditioning system that works 100% of the time, targeting the underlying cause of lubricant failure: chemical breakdown. Backed by patented icb ion-exchange filter, SVR removes acids and dissolved oxidation material as they are generated. Only by managing oxidation levels and removing oxidation material can the root cause of lubricant deposits, or varnish, be eliminated.

Stop Servo Valve Sticking in its Tracks

The ICB ion-exchange filter is manufactured with one goal in mind, to remove the dissolved molecules that accumulate and cause mechanical problems in hydraulic systems and lube oil applications. These filters are based on patented ion exchange technology, combining best-in-class chemistry and materials with precision robotic welding to provide the most robust filter available.

ICB ion-exchange filter is chemically engineered to remove a wide range of contamination, including acid, varnish, and metals. In EHC systems, ICB filters remove the contamination responsible for servo valve sticking, restoring fluid resistivity. ICB filters offer a step-change in performance, protecting system reliability and production with so many benefits beyond acid removal.

Make Informed Decisions with our ACE™ Oil Analysis

At EPT Clean Oil, we specialize in lubricant analysis for critical rotating equipment and EHC systems. We don’t want to be a jack of all trades; our focus is on being the masters of what we do. Each sample that is sent to the Fluid Technical Center is, therefore, examined uniquely.

Our expert chemists drive the advancement of lubricant testing and management through collaboration with industry-leading organizations such as ASTM, STLE, and ICML. We thoroughly review and critically analyze your results before presenting our findings, ensuring precision and reliability. Our commitment is to deliver accurate solutions, always prioritizing quality and providing the insights you need.