Bad Turbomachinery Lubricant or Bad Maintenance?

Users often complain that their turbomachinery lubricant is not performing well because the varnish potential (MPC) number is elevated, or their oil is oxidizing when additives are still present. This drives users to search for a different lubricant or after-market additives when the problem lies with the expectation being placed on the oil – namely that little to no maintenance should be required.

The misconception is that only poor quality lubricants oxidize, and that varnish is a result of improperly formulated oils. While lubricant quality is a key criteria, in reality all lubricants break down due to oxidation – even with additives – and increasing varnish potential over time is normal when dissolved oxidation products are allowed to accumulate.

Rather than discussing more effective varnish removal systems, vendors are now moving the discussion toward synthetic oils and after-market additives to extend the operating range of lubricants with high MPC values. While there is a place for advanced lubricant technologies, simple and more cost effective solutions are available using conventional lubricants to permanently remove dissolved oxidation products and maintain ultra-low MPC values.

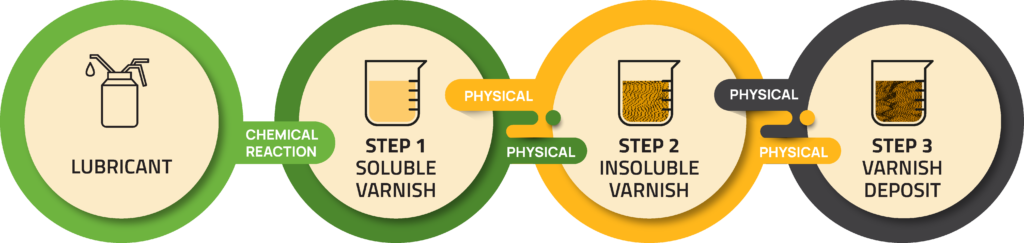

EPT Clean Oil published a technical paper that discusses varnish formation in depth. Oxidation starts on the very first day a lubricant is put into service. The oxidation process creates a dissolved breakdown product, or varnish precursor, that will accumulate in the oil over time until it becomes saturated. Once a saturation point is achieved, these varnish precursors physically convert from the dissolved form into solid deposits.

The saturation point varies throughout the mechanical system due to differences in temperature and pressure, which dictates where varnish deposits will form first. For this reason, it is important to keep the lubricant in an unsaturated state by removing the varnish precursors. By doing so, you can prevent the lubricant from becoming saturated at any temperature or pressure present in the mechanical system and prevent varnish formation.

The below short video animation, offers further information on the varnish formation cycle.