MEET SVR AW FOR ANTI-WEAR HYDRAULIC OIL

Mineral-based hydraulic oils chemically break down from oxygen, heat, and water over time. These three factors are often overlooked and unmanaged within existing fluid maintenance programs as they standardly focus on particulate removal. As a result, varnish pre-cursors dissolved in the oil accumulate, eventually leading to varnish deposits on critical hydraulic components.

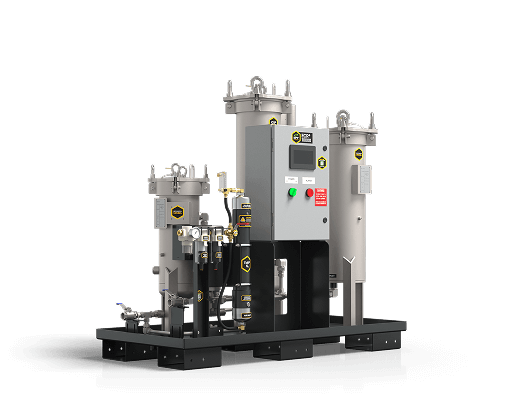

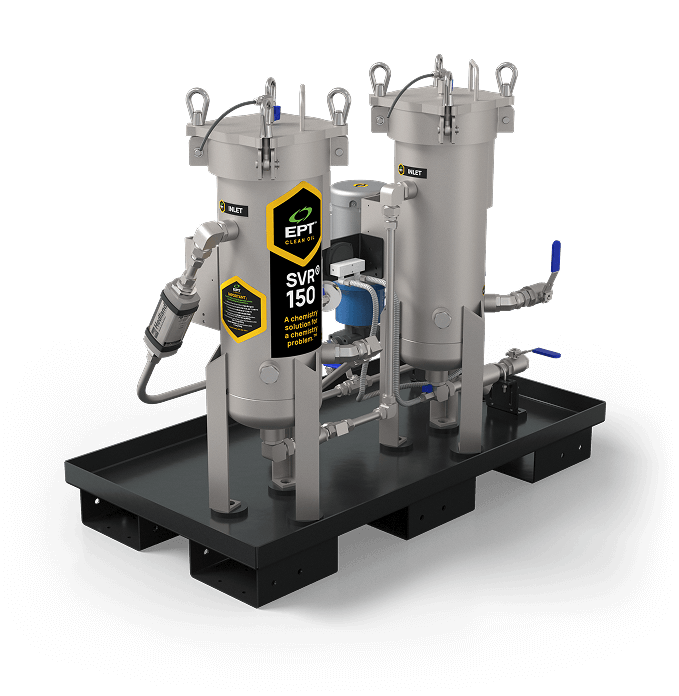

SVR® AW is an engineered dialysis-style conditioning system that works 24/7, removing both dissolved varnish pre-cursors and varnish particles. Backed by patented ion-exchange technology, ICB® AW, SVR works during hydraulic system operation as oxidation material is generated, preventing the accumulation of varnish, and eliminating the root cause of oil varnishing.

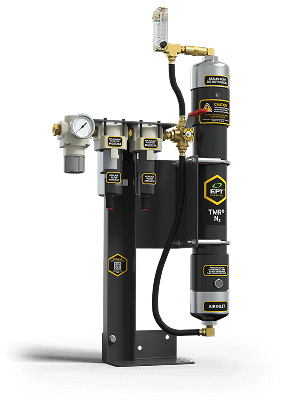

Using SVR to remove both forms of varnish while removing oxygen and water with TMR® N2 offers a complete step-change in hydraulic oil maintenance, maintaining oils in ideal operating condition – free of varnish water and at ultra-low particle levels, significantly extending oil life.

CASE STUDY

This case explores how advanced solutions with the SVR and ICB AW Filters helped reduce MPC varnish potential by 87%.

SVR AW Features and Benefits

- Utilizes patented ICB AW ion-exchange technology to eliminate soluble varnish at the molecular level, preventing the oil from becoming saturated and forming varnish deposits

- Maintains consistent fluid quality and performance

- Restores normal MPC varnish potential

- Removes water and oxygen levels with the recommended TMR® N2 add-on, further decreasing fluid breakdown, significantly extending oil life

- Avoids flushing and related downtime

- Manufactured to ISO 9001 Standards

- Eliminates the need for expensive after-market additives

- Low maintenance: Turn it on and let it run; that’s it

- No downtime – SVR AW can be installed without an outage

SVR AW System Sizing for Anti-wear Hydraulic Oil Maintenance

For regular hydraulic oil maintenance, the desired flow rate is to exchange the fluid reservoir volume 1-2x per day.

| SVR® HYDRO | SVR® 150 | SVR® 300 | SVR® 600 | SVR® 1200 | |

|  |  |  |  | |

| Reservoir Volume (Mineral Oil) | Minimum: 2,500 L/ 660 gal Maximum: 15,000 L / 3,963 gal | Minimum: 715 L / 189 gal Maximum: 2,870 L / 758 gal | Minimum: 1,440 L / 380 gal Maximum: 5,740 L / 1,516 gal | Minimum: 3,785 L / 1,000 gal Maximum: 16,278 L / 4,300 gal | Minimum: 5,980 L / 1,579 gal Maximum: 27,255 L / 7,200 gal |

| Reservoir Volume (Synthetic Oil) | Minimum: 240 L / 63 gal Maximum: 960 L / 253 gal | Minimum: 480 L / 126 gal Maximum: 1,912 L / 505 gal | Minimum: 1,435 L / 379 gal Maximum: 5,680 L / 1,500 gal | Minimum: 2,272 L / 600 gal Maximum: 9,085 L / 2,400 gal | |

| ICB Flow Rate | 19.0 lpm / 5.0 gpm | 2.0 lpm / 0.5 gpm | 4.0 lpm / 1.0 gpm | 12.0 lpm / 3.0 gpm | 19.0 lpm / 5.0 gpm |

| System flow rate through high efficiency filtration | 38.61 lpm / 10.2 gpm | 8.0 lpm / 2.1 gpm | 8.0 lpm / 2.1 gpm | 38.61 lpm / 10.2 gpm | 38.61 lpm / 10.2 gpm |

| ICB Filter Model | RO | RO FRF JET AW | JRO FRF JET AW | RO FRF JET AW | RO FRF JET AW |

| Fluid Applications | Rust and oxidation turbine oil only at this time | Rust & Oxidation Turbine Oil (RO) Phosphate Ester Fluid (FRF) Aeroderivative Turbine Oil (JET) Anti-Wear Hydraulic Oil (AW) | Rust & Oxidation Turbine Oil (RO) Phosphate Ester Fluid (FRF) Aeroderivative Turbine Oil (JET) Anti-Wear Hydraulic Oil (AW) | Rust & Oxidation Turbine Oil (RO) Phosphate Ester Fluid (FRF) Aeroderivative Turbine Oil (JET) Anti-Wear Hydraulic Oil (AW) | Rust & Oxidation Turbine Oil (RO) Phosphate Ester Fluid (FRF) Aeroderivative Turbine Oil (JET) Anti-Wear Hydraulic Oil (AW) |

| Other Proprietary Filters and System Requirements | TMR® AquaPurge Coalescer | For synthetic oils, it is advised to combine a TMR® N2 for water removal | For synthetic oils, it is advised to combine a TMR® N2 for water removal | For synthetic oils, it is advised to combine a TMR® N2 for water removal | For synthetic oils, it is advised to combine a TMR® N2 for water removal |

| Contaminant Targets | Soluble Varnish Insoluble Varnish Oxidation by-products Water Particulate removal | Soluble Varnish Insoluble Varnish Particulate removal | Soluble Varnish Insoluble Varnish Particulate removal | Soluble Varnish Insoluble Varnish Particulate removal | Soluble Varnish Insoluble Varnish Particulate removal |

| Electrical Options | General Purpose electrical only at this time | General Purpose with 50 Hz and 60 Hz electrical voltage options CSA Class 1 Div 1 Group C&D with 50 Hz and 60Hz electrical voltage options CSA Class 1 Div 2 Group A, B, C & D with 50 Hz and 60 Hz electrical voltage options IECeX and ATEX-approved configurations are available. Please get in touch with us for more information. | General Purpose with 50 Hz and 60 Hz electrical voltage options CSA Class 1 Div 1 Group C&D with 50 Hz and 60Hz electrical voltage options CSA Class 1 Div 2 Group A, B, C & D with 50 Hz and 60 Hz electrical voltage options IECeX and ATEX-approved configurations are available. Please get in touch with us for more information. | General Purpose with 50 Hz and 60 Hz electrical voltage options CSA Class 1 Div 1 Group C&D with 50 Hz and 60Hz electrical voltage options CSA Class 1 Div 2 Group A, B, C & D with 50 Hz and 60 Hz electrical voltage options IECeX and ATEX-approved configurations are available. Please get in touch with us for more information. | General Purpose with 50 Hz and 60 Hz electrical voltage options CSA Class 1 Div 1 Group C&D with 50 Hz and 60Hz electrical voltage options CSA Class 1 Div 2 Group A, B, C & D with 50 Hz and 60 Hz electrical voltage options IECeX and ATEX-approved configurations are available. Please get in touch with us for more information. |

Get a Complete Picture of Your Anti-Wear Hydraulic Oil

EPT Clean Oil’s Fluid Technical Center is a state-of-the-art lubricant research facility, offering specialized analysis and comprehensive evaluations for your anti-wear hydraulic oil.

Our Lube Oil test package, applicable for mineral-based anti-wear hydraulic oils, includes:

- Acid Number

- MPC Varnish Potential

- Antioxidant and AW Additive Levels

- Viscosity (40°C)

- Water

- ISO Particle Count

- Dissolved Metals

- Fluid Color

Submit an oil sample today, and let’s get a handle on the remaining life of your anti-wear hydraulic oil.