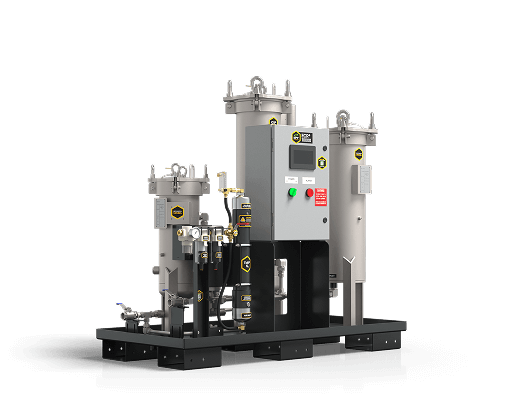

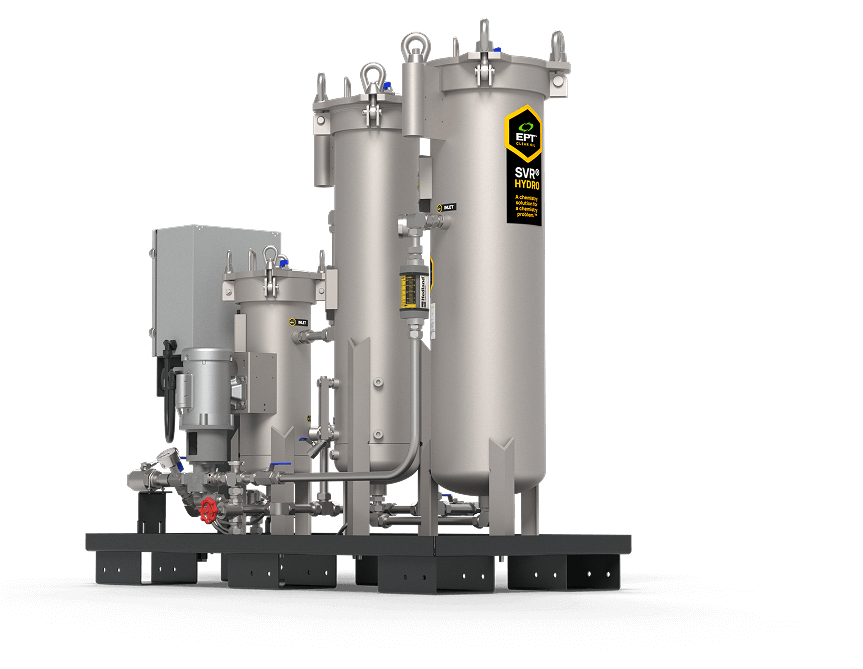

Get the Wet Out with SVR® HYDRO

SVR® HYDRO coalesce system boasts three technologies in one advanced skid-mounted kidney loop filtration system offering a complete lubricant chemistry management solution. Through advanced filtration technologies, including molecular contamination adsorption with patented ICB® ion-exchange filtration, proprietary mechanical coalescing and micro-filtration, SVR HYDRO restores and protects lubricants from acid, varnish, particulate, and free and emulsified water, in an energy-efficient and expedient manner.

- Varnish and Acid Control

- Water Separation and Removal

- Particulate Removal

- Additive Protection

The SVR HYDRO eliminates breakdown products that previously limited the effectiveness of water separation technologies, including coalescers. It focuses on oil-water separation, water removal, and lubricant chemistry management.

SVR HYDRO: Complete Three-Stage Filtration System Offering Comprehensive Lubricant Chemistry Management

Integrating emulsion-reducing ICB ion exchange and TMR® AquaPurge coalescer technologies creates a synergistic effect, enhancing the overall efficiency of water removal in lubricating oil systems.

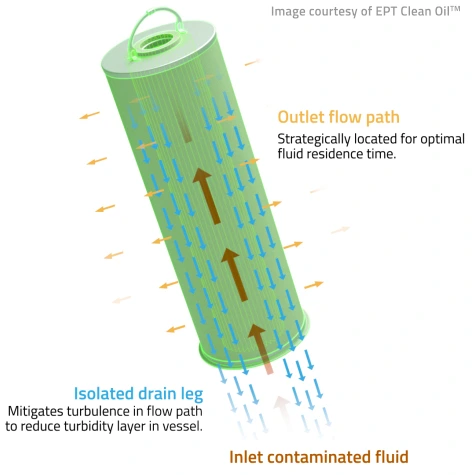

1.

Pre-treatment with patented ICB ion-exchange: reduces the amount of emulsified water before the oil even reaches the coalescer.

- ICB ion-exchange resins remove the dissolved contaminants that stabilize oil-water emulsions, allowing the coalescer to function more effectively.

- This pre-treatment breaks down stable oil-water emulsions, reducing the load on the TMR AquaPurge Coalescer and improving its efficiency.

2.

TMR AquaPurge Coalescer: removes the remaining free water and any less stable emulsions.

- This two-step process ensures a more thorough removal of free and emulsified water than previously possible.

- The coalescer more effectively merges and separates water into larger droplets after the ICB ion-exchange process.

3.

High-efficiency Particulate Removal: removes any remaining solid contamination.

- The final phase, the clean-up phase, involves the fluid passing through a high-efficiency particulate filter element to remove contaminants that precipitated during Phase 2 or Phase 3.

CASE STUDY

This case explores how advanced solutions with the SVR HYDRO helped resolve the issue and prevent further disruptions.

Operational Advantages of SVR HYDRO

- Enhanced Water Removal: The combination of ICB ion-exchange and TMR AquaPurge Coalescer technologies allows for more effective water removal, addressing the dissolved and emulsified water that a single technology will likely struggle with.

- Prolonged Oil Life: This hybrid approach effectively removes water and other contaminants, maintaining the lubricant’s quality and extending its service life.

- Reduced Maintenance and Increased Uptime: Better water removal minimizes the risk of failure, corrosion, oxidation, and other water-related issues, reducing maintenance and downtime. SVR HYDRO also extends service intervals with a maintenance-friendly design and redundant fail safes, mitigating mechanical failure risks and providing worry-free operation.

- Significant Energy Savings: Uses only 15% of the energy required for traditional water-removal technologies.

- Reduced Footprint: An integrated solution that addresses all water-removal needs by preventing emulsion formation and effectively removing any water that enters a lube oil system.

- Automatic Water Leg Drain: EPT Clean Oil’s unique PLC control logic allows for worry-free, unattended operation with auto water drain features and redundant fail-safe control logic. The SVR HYDRO also offers a built-in water leg counter to track water removal performance and efficiency.

Meet SVR® HYDRO

WatchSVR® HYDRO Features and Benefits:

- Addresses the root cause of poor oil-water separation, knocking down oxidative material to break and prevent emulsion formation.

- A simple, sophisticated, easy-to-operate system marries three filtration phases into one advanced lube oil conditioning system to deliver reduced lifecycle costs.

- 15% of the energy consumption of vacuum dehydration and single-pass water removal efficiencies of up to 90%, allowing for multi-pass water removal to < 200 ppm.

- Automatic water leg drain, leg counter tracking cycles, redundant fail-safes, offering worry-free operations.

- Extended oil service intervals, reduced equipment maintenance requirements and increased performance and uptime.

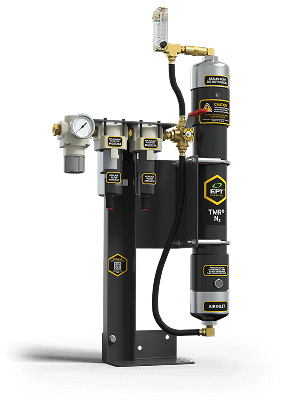

TMR® AquaPurge Coalescer

The TMR® AquaPurge Coalescer is an innovative, integrated coalesce and separator technology that rapidly and efficiently removes two forms of water: emulsified and free. Utilizing synthetic hydrophobic membranes to repel water while allowing oil to pass through, this multi-chamber coalescer offers single-pass water-removal efficiencies of up to 90%, allowing for multi-pass water removal to < 200 ppm.

Integrating emulsion-reducing ICB® ion exchange and TMR AquaPurge Coalescer technologies creates a synergistic effect. ICB ion exchange removes the dissolved contaminants that stabilize oil-water emulsions, and TMR AquaPurge Coalescer removes the remaining free water and less stable emulsions, enhancing the overall efficiency of water removal in lubricating oil systems.

Meet TMR® AquaPurge Coalescer

WatchMake Informed Decisions with our ACE™ Oil Analysis

At EPT Clean Oil, we specialize in lubricant analysis for critical rotating equipment and EHC systems. We don’t want to be a jack of all trades; our focus is on being the masters of what we do. Each sample that is sent to the Fluid Technical Center is, therefore, examined uniquely.

Our expert chemists drive the advancement of lubricant testing and management through collaboration with industry-leading organizations such as ASTM, STLE, and ICML. We thoroughly review and critically analyze your results before presenting our findings, ensuring precision and reliability. Our commitment is to deliver accurate solutions, always prioritizing quality and providing the insights you need.