Best in Class Phosphate Ester-Based EHC Fluid Chemistry Management

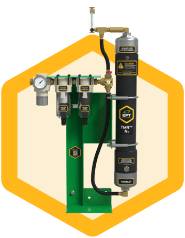

ECR® 10000 is an integrated skid-mounted kidney loop filtration system designed for phosphate ester fluid, primarily electro-hydraulic control (EHC) applications, equipped with four proprietary filtration technologies to achieve fluid standards as defined in ASTM D8323-20.

The four filtration technologies include:

- Electrostatics

- Patented ICB® ion-exchange

- High-efficiency particulate removal

- TMR® N2 water removal

Phase One: Water Content Management

TMR N2 introduces high-purity nitrogen (≥97%), insulating the reservoir, mitigating fluid contact with oxygen and atmospheric water regression, and eliminating factors that cause oxidation. Continuous inclusion and operation of the TMR ensures water content is maintained within the ideal target range between 200 and 500 ppm.

Phase Two: Sub-micron Particulate Removal

Solid contamination is removed with electrostatic Collector elements, engineered to remove sub-micron (<4 micron) particles that are too fine to be captured with normal filters. Fine particulate contaminants pass through these filtration systems, impacting fluid life and component wear. The proprietary ECR Collector media removes hard and soft contaminants as small as 0.01 microns through electrophoretic and dielectrophoretic processes.

Phase Three: Dissolved Contamination Removal

Dissolved contamination is addressed with patented ICB® ion-exchange filters, engineered to remove acids and soluble varnish at the molecular level. Other acid-scavengers are unable to remove phosphate ester varnish and its precursors.

Phase Four: Additional Solid Contamination Removal

The last and final phase is the clean-up phase, with the fluid passing through a high-efficiency particulate filter element, removing contaminants that have come out of solution during Phase 2 or 3.

ECR 10000 unites four leading filtration technologies within one integrated system to maintain the quality, life and reliability of your EHC fluids.

Meet ECR® 10000

WatchEliminate Phosphate Ester Fluid Contamination

Target both categories of solid contamination in phosphate ester fluids with ECR 10000.

>4 micron particulate measured and classified by ISO 11500/4406

<4 micron particulate, which is not measured

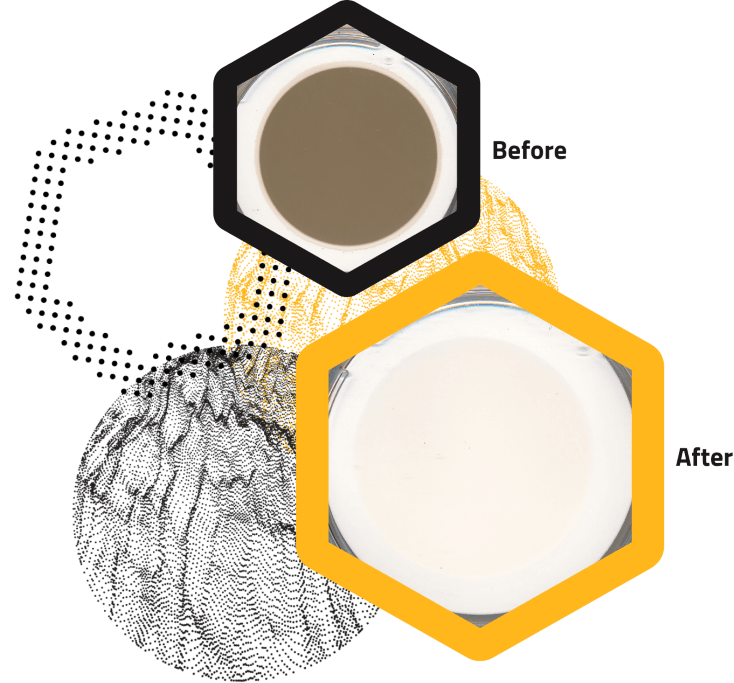

Particulate contamination <4 microns, resulting from micro-dieseling (temperature fluid breakdown caused by air release issues), is responsible for fluid darkening. ECR 10000 removes this sub-micron particulate contamination, which is integral in managing phosphate ester fluid quality.

ECR® 10000 Features and Benefits:

• Best-in-class performance for acid number and fluid resistivity improvement

• Removes carbon produced from micro dieseling and restores fluid color

• Reduces patch weight by up to 98% or < 4mg / 50ml fluid

• Protects servo valves from mechanical wear

• Reduces total dirt load typically by 75% (by mass) or more

• Decreases air entrainment and increases resistivity

When used as directed and as part of proper fluid maintenance programs, ECR 10000 improves fluid colour, increases resistivity and removes acid and varnish, which is integral in managing phosphate ester fluid quality. In conjunction with TMR® N2 for water removal, comprehensive fluid chemistry management is achieved, eliminating the need for chemical flushes when maintained over time.

| Fluid Property | ASTM D8323 Limit | Competing System | ECR 10000 |

|---|---|---|---|

| Acid Number | ≤0.10 |  |  |

| MPC | ΔE≤20 |  | |

| Patch weight | ≤4mg/50ml |  | |

| Phenol | <8000 |  | |

| Metals | <10 ppm total |  | |

| Resistivity | >10 GΩcm |  | |

| ASTM Color | ≤6 |  |

ECR® Collector Elements

Collector elements are designed for ECR® electrostatic oil cleaners. ECR Collector elements are not classified as filters as they do not remove particles by their physical size, but rather their weight. Collectors are used to remove sub micron particulates in EHC fluid systems that are below the range of ISO4406.

ECR collectors are the opposite of our patented ICB® FRF ion-exchange filters which focus on acid and varnish removal. For complete Lubricant Chemistry Management and to address the contamination equation, ECR Collectors should be used along with ICB FRF ion-exchange filters and our TMR® N2 system.