Premium Proactive Engineering (PPE)

Over the past few years, our distributor partner in Iraq, Premium Proactive Engineering (PPE), has made remarkable strides in the region, with a focus on Reliability and Condition Monitoring in Iraq. They are a team of highly capable and professional engineers, adding to our movement of Lubricant Chemistry Management alumni.

ECR® Conditioning Skid

Application: Steam Turbine

Location: Iraq

Problem: Within this steam turbine, three critical issues were affecting the reliability. First, the plant was experiencing frequent unit trips due to servo valve failures, primarily caused by varnish deposits on the valves. Second, the system consistently recorded high acid numbers, with a maximum of 2.7 mg KOH/mL, which put the equipment at significant risk and increased maintenance costs. And finally, third, phosphate ester oil, known for its fire-resistant properties, is both complicated to manage and very expensive.

Solution: When EPT Clean Oil™ and our Fluid Technical Center team were consulted, the ECR® Conditioning Skid was recommended, our first-generation skid for electro-hydraulic control (EHC) applications, which has now evolved to our ECR 10000, offering comprehensive contamination removal targeting acid, varnish, demulsibility, resistivity and sub-micron contamination.

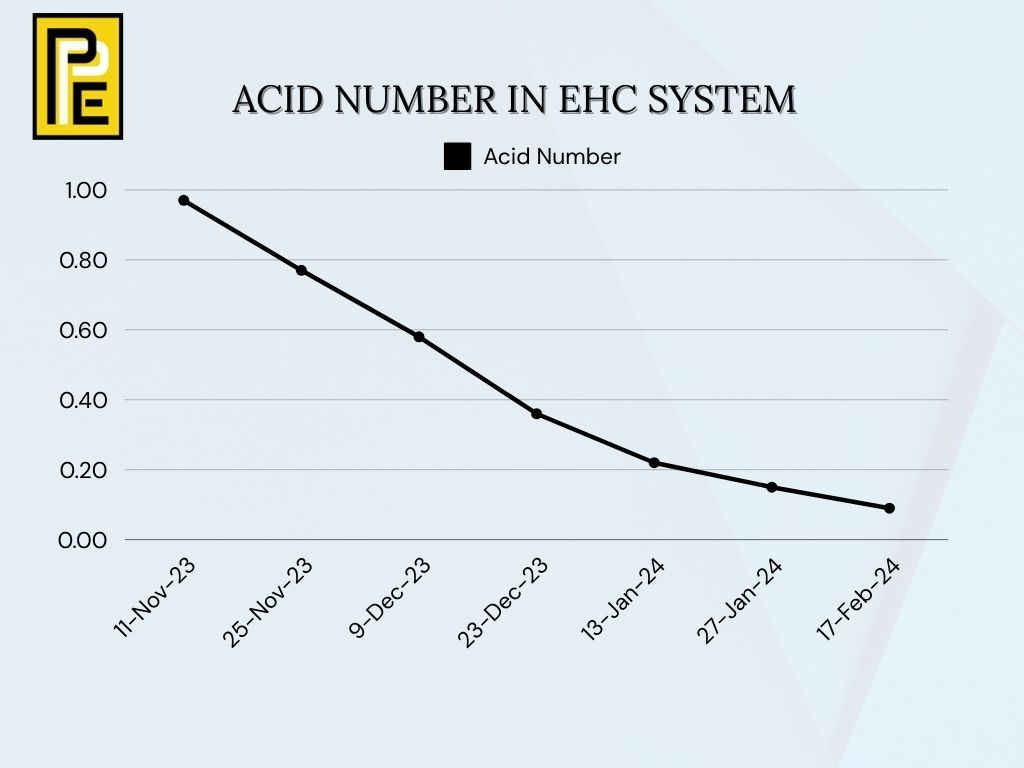

Results: Throughout the operation of our ECR Conditioning Skid, the acid number was closely monitored to ensure the oil remained within the specifications outlined in ASTM D8323 standards. Initially, the oil was already at a severe condemn level. However, after a period of operation with our ECR , we observed a significant 92% reduction in the acid number, which continues to improve.

The oil costs have already been reduced by an impressive $750,000, and we anticipate maintaining these savings over the next 18 months. Achieving a 1,000% ROI within just one year demonstrates the effectiveness of our approach.

While the case study above highlighted the successes of the ECR conditioning skid, we also want to emphasize this remarkable achievement PPE has made with the SVR 1200 and the patented ICB® Ion-Exchange technology.

SVR® 1200

Application: Siemens steam turbine (SST-5000)

Location: Iraq

Problem: The system was experiencing extremely high particle contamination and poor water separation efficiency, which negatively impacted its overall performance. Left untreated, it would lead to inevitable downtime.

Solution: The SVR® varnish removal system equipped with EPT Clean Oil’s patented ICB® ion-exchange filters was recommended to address these issues effectively. SVR offers a comprehensive solution for turbine lubricant recovery, removing varnish precursors and oxidation byproducts, restoring oil solvency, and preventing varnish formation. Using patented ICB technology,the SVR extends oil life and helps prevent varnish formation, thereby restoring oil health.

Think of the SVR as the frame, and the ICB filters as the engine; without the filters, the skid is just a shell, the innovation and technology are inside.

Results: The system achieved a significant improvement, with particle count decreasing from 1700 particles per mL to just 100 particles per mL, while demulsibility was enhanced by an impressive 83%.