MEET SVR FRF FOR PHOSPHATE ESTER FLUIDS

Phosphate ester fluids are the preferred hydraulic fluid for electro-hydraulic control (EHC) systems due to their excellent fire-resistant properties. Suffering from unnecessarily high acid production levels, these fluids are challenging to maintain, demanding additional fluid maintenance and chemistry management. Standard acid filters aren’t enough, often contributing to fluid breakdown and equipment failure as they don’t address fluid chemistry.

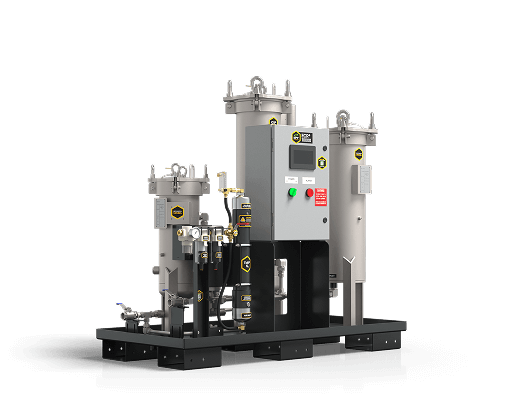

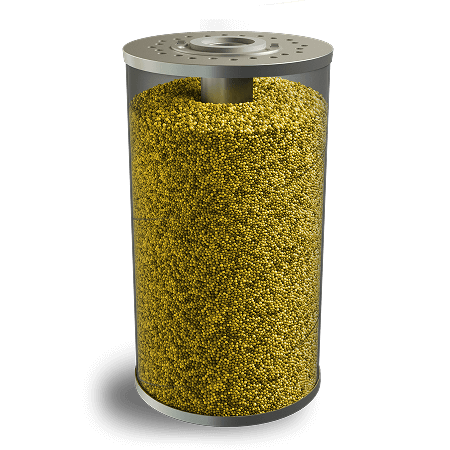

SVR® FRF is an engineered dialysis-style fluid conditioning system backed by patented ICB® FRF ion-exchange technology and best-in-class mechanical filtration to fully manage and maintain phosphate ester fluids. Based on 30+ years of dedicated experience, the SVR FRF design meets the requirements for nuclear applications addressing fluid chemistry to mitigate high acid levels, gel formation, and rampant varnish and return fluid quality to operating specifications without flushing or fluid change.

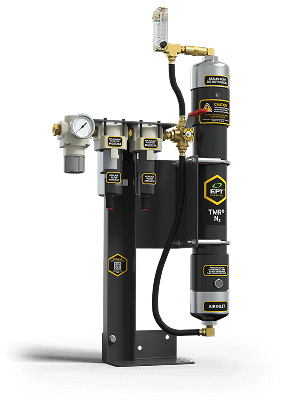

Combined with our TMR® N2 water removal system, the primary breakdown pathway of phosphate ester fluids can be fully managed. This combined approach removes up to 10x more contamination, controlling the rate of fluid breakdown and providing best-in-class protection against EHC system failures and lost revenue.

CASE STUDY

This case explores how advanced solutions with the SVR FRF helped reduce varnish potential by 95%.

CASE STUDY

This case study highlights varnish potential and resistivity being brought back into specification after installing an SVR® FRF.

SVR FRF Features and Benefits

- Utilizes patented ICB® FRF ion-exchange technology to remove acids, dissolved metals, varnish and varnish precursors

- Protects servo valves by eliminating the contamination that would otherwise cause valve sticking or slow valve response time

- Offers the highest acid removal capacity available on the market, maintaining Acid Number to <0.09

- Significantly improves fluid resistivity

- Significantly reduces ISO particle-counts

- Reduces water by 150 PPM per day and maintains water <300ppm, as well as lowers oxygen levels, further decreasing fluid breakdown and harmful dissolved gases including O2, CO, H and C2C4 with the recommended TMR® N2 system add-on

- Significantly extends fluid operating life

- Eliminates the need for flushing

- Manufactured to ISO 9001 standards

- Small footprint and straightforward plumbing

- Low maintenance: Turn it on and let it run; that’s it!

- No downtime – SVR FRF can be installed without an outage

SVR FRF owners gain access to a complete support program, including complimentary oil analysis and expert interpretation from our professional and Ph.D. Chemists until results have been documented. After results have been confirmed, owners are given the option to continue the analysis program for a quarterly fee.

SVR FRF Sizing Comparison Chart

| SVR® HYDRO | SVR® 150 | SVR® 300 | SVR® 600 | SVR® 1200 | |

|  |  |  |  | |

| Reservoir Volume (Mineral Oil) | Minimum: 2,500 L/ 660 gal Maximum: 15,000 L / 3,963 gal | Minimum: 715 L / 189 gal Maximum: 2,870 L / 758 gal | Minimum: 1,440 L / 380 gal Maximum: 5,740 L / 1,516 gal | Minimum: 3,785 L / 1,000 gal Maximum: 16,278 L / 4,300 gal | Minimum: 5,980 L / 1,579 gal Maximum: 27,255 L / 7,200 gal |

| Reservoir Volume (Synthetic Oil) | Minimum: 240 L / 63 gal Maximum: 960 L / 253 gal | Minimum: 480 L / 126 gal Maximum: 1,912 L / 505 gal | Minimum: 1,435 L / 379 gal Maximum: 5,680 L / 1,500 gal | Minimum: 2,272 L / 600 gal Maximum: 9,085 L / 2,400 gal | |

| ICB Flow Rate | 19.0 lpm / 5.0 gpm | 2.0 lpm / 0.5 gpm | 4.0 lpm / 1.0 gpm | 12.0 lpm / 3.0 gpm | 19.0 lpm / 5.0 gpm |

| System flow rate through high efficiency filtration | 38.61 lpm / 10.2 gpm | 8.0 lpm / 2.1 gpm | 8.0 lpm / 2.1 gpm | 38.61 lpm / 10.2 gpm | 38.61 lpm / 10.2 gpm |

| ICB Filter Model | RO | RO FRF JET AW | JRO FRF JET AW | RO FRF JET AW | RO FRF JET AW |

| Fluid Applications | Rust and oxidation turbine oil only at this time | Rust & Oxidation Turbine Oil (RO) Phosphate Ester Fluid (FRF) Aeroderivative Turbine Oil (JET) Anti-Wear Hydraulic Oil (AW) | Rust & Oxidation Turbine Oil (RO) Phosphate Ester Fluid (FRF) Aeroderivative Turbine Oil (JET) Anti-Wear Hydraulic Oil (AW) | Rust & Oxidation Turbine Oil (RO) Phosphate Ester Fluid (FRF) Aeroderivative Turbine Oil (JET) Anti-Wear Hydraulic Oil (AW) | Rust & Oxidation Turbine Oil (RO) Phosphate Ester Fluid (FRF) Aeroderivative Turbine Oil (JET) Anti-Wear Hydraulic Oil (AW) |

| Other Proprietary Filters and System Requirements | TMR® AquaPurge Coalescer | For synthetic oils, it is advised to combine a TMR® N2 for water removal | For synthetic oils, it is advised to combine a TMR® N2 for water removal | For synthetic oils, it is advised to combine a TMR® N2 for water removal | For synthetic oils, it is advised to combine a TMR® N2 for water removal |

| Contaminant Targets | Soluble Varnish Insoluble Varnish Oxidation by-products Water Particulate removal | Soluble Varnish Insoluble Varnish Particulate removal | Soluble Varnish Insoluble Varnish Particulate removal | Soluble Varnish Insoluble Varnish Particulate removal | Soluble Varnish Insoluble Varnish Particulate removal |

| Electrical Options | General Purpose electrical only at this time | General Purpose with 50 Hz and 60 Hz electrical voltage options CSA Class 1 Div 1 Group C&D with 50 Hz and 60Hz electrical voltage options CSA Class 1 Div 2 Group A, B, C & D with 50 Hz and 60 Hz electrical voltage options IECeX and ATEX-approved configurations are available. Please get in touch with us for more information. | General Purpose with 50 Hz and 60 Hz electrical voltage options CSA Class 1 Div 1 Group C&D with 50 Hz and 60Hz electrical voltage options CSA Class 1 Div 2 Group A, B, C & D with 50 Hz and 60 Hz electrical voltage options IECeX and ATEX-approved configurations are available. Please get in touch with us for more information. | General Purpose with 50 Hz and 60 Hz electrical voltage options CSA Class 1 Div 1 Group C&D with 50 Hz and 60Hz electrical voltage options CSA Class 1 Div 2 Group A, B, C & D with 50 Hz and 60 Hz electrical voltage options IECeX and ATEX-approved configurations are available. Please get in touch with us for more information. | General Purpose with 50 Hz and 60 Hz electrical voltage options CSA Class 1 Div 1 Group C&D with 50 Hz and 60Hz electrical voltage options CSA Class 1 Div 2 Group A, B, C & D with 50 Hz and 60 Hz electrical voltage options IECeX and ATEX-approved configurations are available. Please get in touch with us for more information. |

Get a Complete Picture of Your Fluid Condition to ASTM D8323 Standards

EPT Clean Oil’s Fluid Technical Center is a state-of-the-art lubricant research facility, offering specialized analysis and comprehensive evaluations of your phosphate ester fluid’s condition as per the guidelines provided in ASTM D8323.

Our Phosphate Ester test package, applicable for electrohydraulic control (EHC) oils and fire-resistant fluids, includes:

- Viscosity (40°C)

- Water Content

- ISO Particle Count

- Dissolved Metals

- Fluid Color

- Acid Number

- MPC Varnish Potential

- Resistivity (20°C)

- Phenol Levels

Submit a sample a fluid sample today and let’s get a handle on the condition of your phosphate ester fluid.

Case Study: ROI of 680% with SVR FRF

A peer-reviewed ASTM article reported the economic impact of operating SVR and ICB technology since 1992 on 100 turbines in Canada.

- Reduced environmental waste by 19 million pounds (9,047 pounds per turbine per year)

- Significantly reduced lubricant maintenance costs saving $1 Million per turbine since 1992

- Reduced equipment failure to nil, saving $13.4 million per year

- Generated an ROI of 680%, excluding mechanical failure reductions

Based on the high failure costs before 1992, the continued usage of phosphate ester may have been considered economically unviable unless fluid purification was adopted utilizing SVR FRF and ICB FRF.