Next Generation ECR Phosphate Ester Conditioning Systems

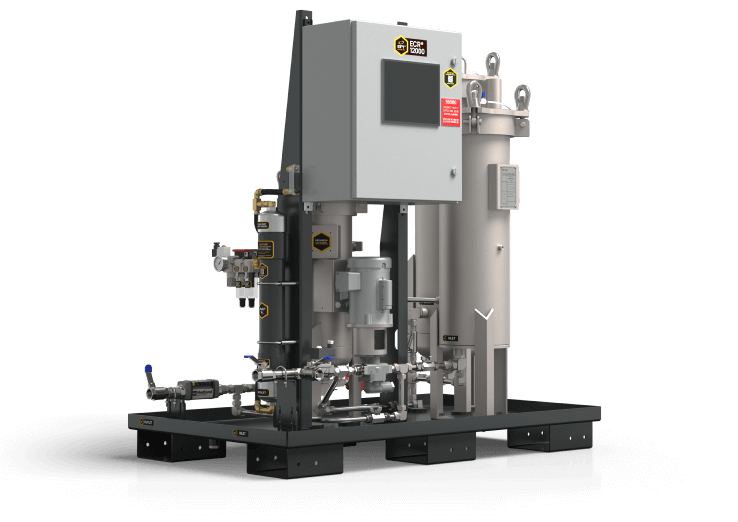

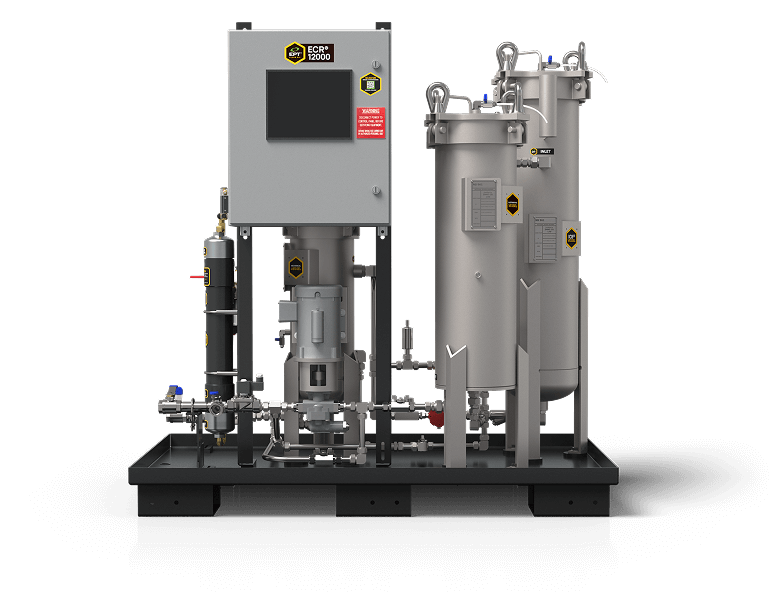

ECR® 12000

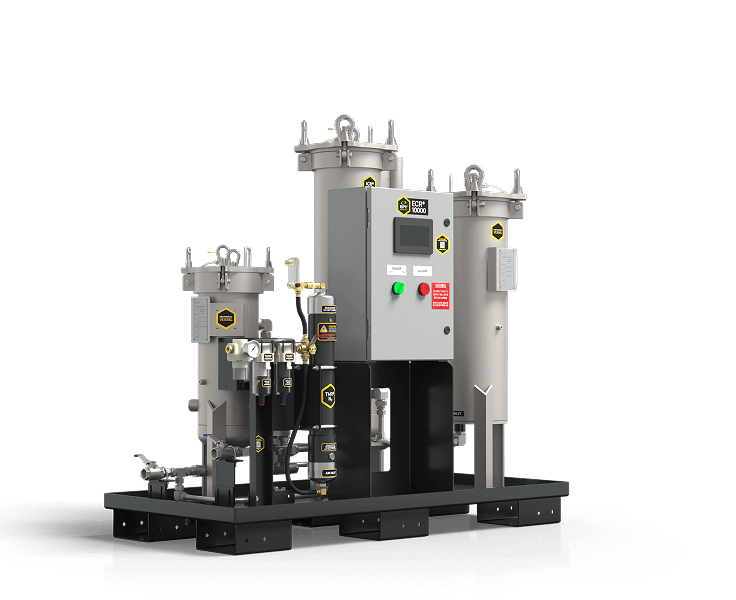

ECR® 10000

Meet the System Match for ECR Collector Element

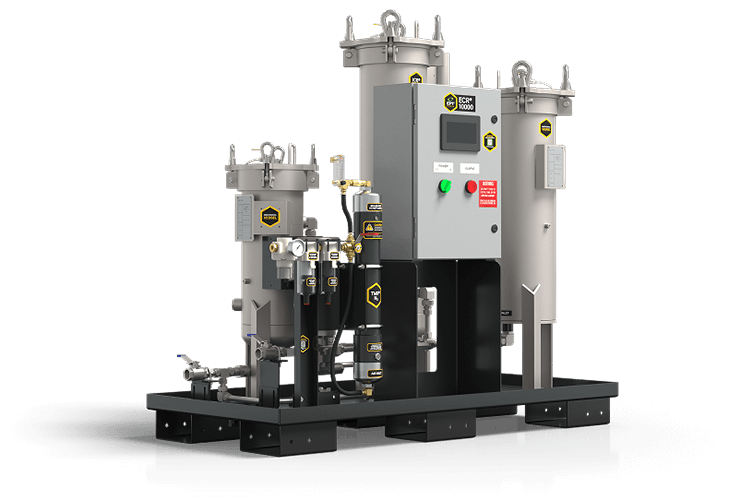

ECR® 12000 Phosphate Ester Conditioning Skid

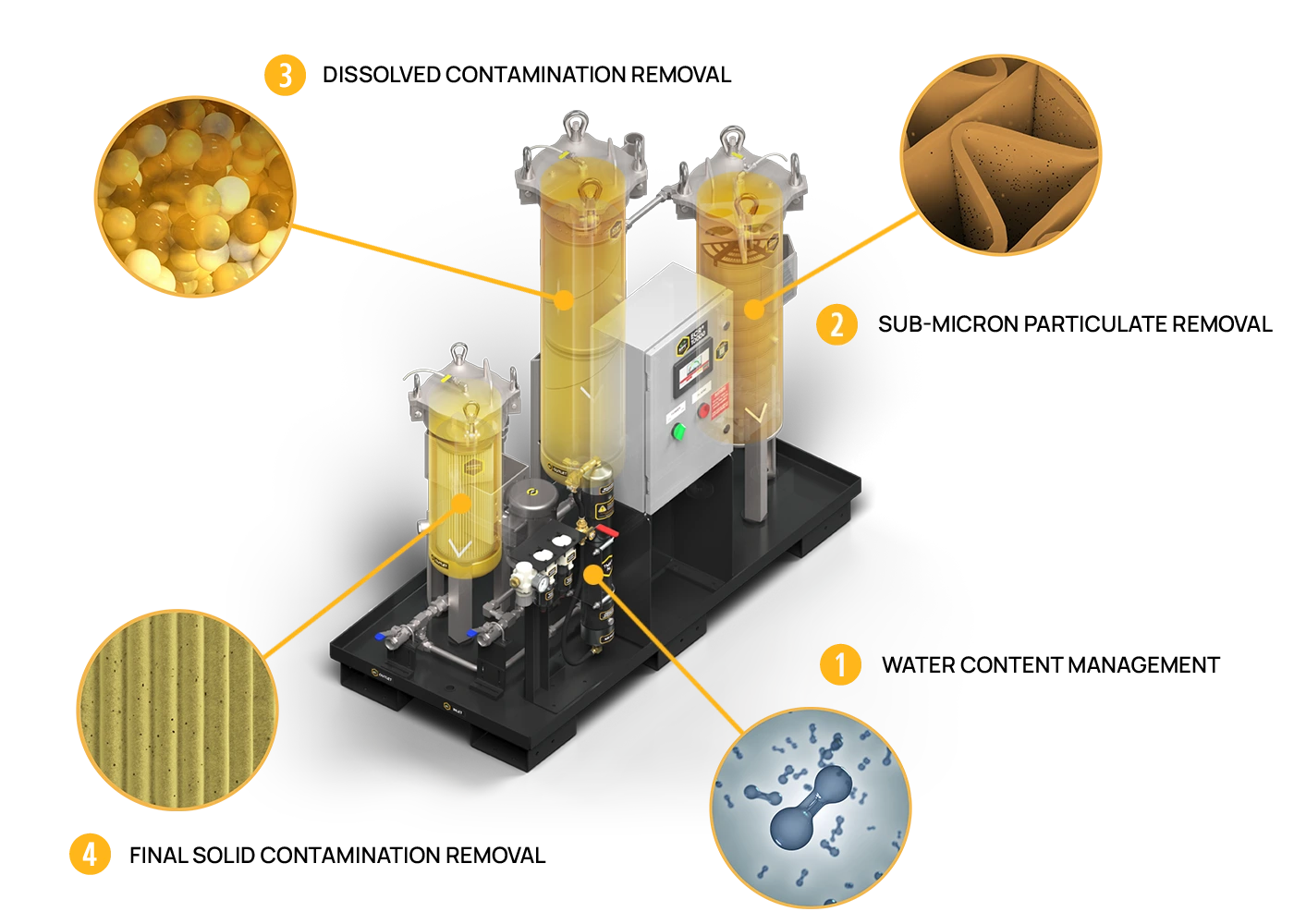

The ECR® 12000 is an enhanced capability, integrated, skid-based filtration system designed for phosphate ester fluid, primarily used in electro-hydraulic control (EHC) applications. ECR 12000 is equipped with four proprietary filtration technologies, and inline sensing capabilities to achieve fluid standards as defined in ASTM D8323-24.

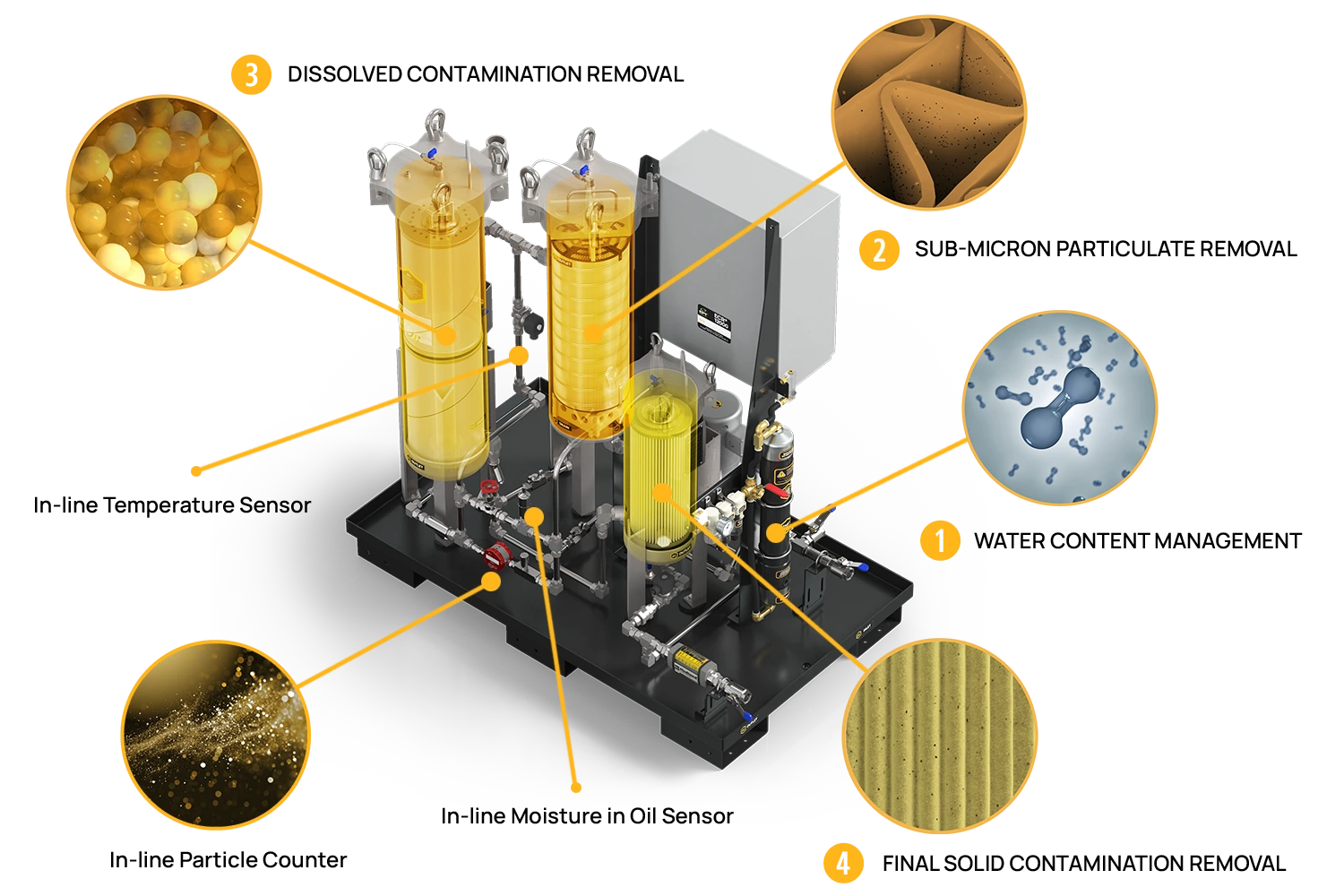

The four filtration technologies are:

- ECR electrostatics

- Patented ICB® ion-exchange

- High-efficiency particulate removal

- TMR® N2 water removal

The ECR 12000 also tracks the following fluid properties and delivers comprehensive daily reports directly to your inbox or for download:

- Temperature

- ISO Particle Count

- Water Content

Phase

1

WATER CONTENT MANAGEMENT

TMR N2 introduces high-purity, dry nitrogen (≥97%) to insulate the reservoir, reducing fluid exposure to oxygen and atmospheric water, thus preventing oxidation and hydrolysis. Continuous operation keeps water content within the ideal range of 200 to 500 ppm.

Phase

2

SUB-MICRON PARTICULATE REMOVAL

ECR Collector elements remove sub-micron particles(<4 microns) that standard filters miss, enhancing fluid life and reducing component wear. ECR Collector media captures contaminants as small as 0.01 microns through advanced electrostatic filtration processes.

Phase

3

DISSOLVED CONTAMINATION REMOVAL

Patented ICB ion-exchange filters eliminate acids and soluble varnish at the molecular level, effectively removing harmful phosphate ester varnish and acids. This enhances EHC fluid stability and significantly extends its lifetime.

Phase

4

FINAL SOLID CONTAMINATION REMOVAL

A high-efficiency particulate filter polishes EHC fluids to ensure their maximum cleanliness.

Meet ECR® 12000

WatchCASE STUDY

In this case study, the ECR 12000 technology was applied in service for over 12 months, delivering substantial benefits to the end user.

CASE STUDY

In this video interview, we record live testimonial from an end-user to understand their experience and overall rating of the ECR 12000. Your new favorite two words might be 99% reduced.

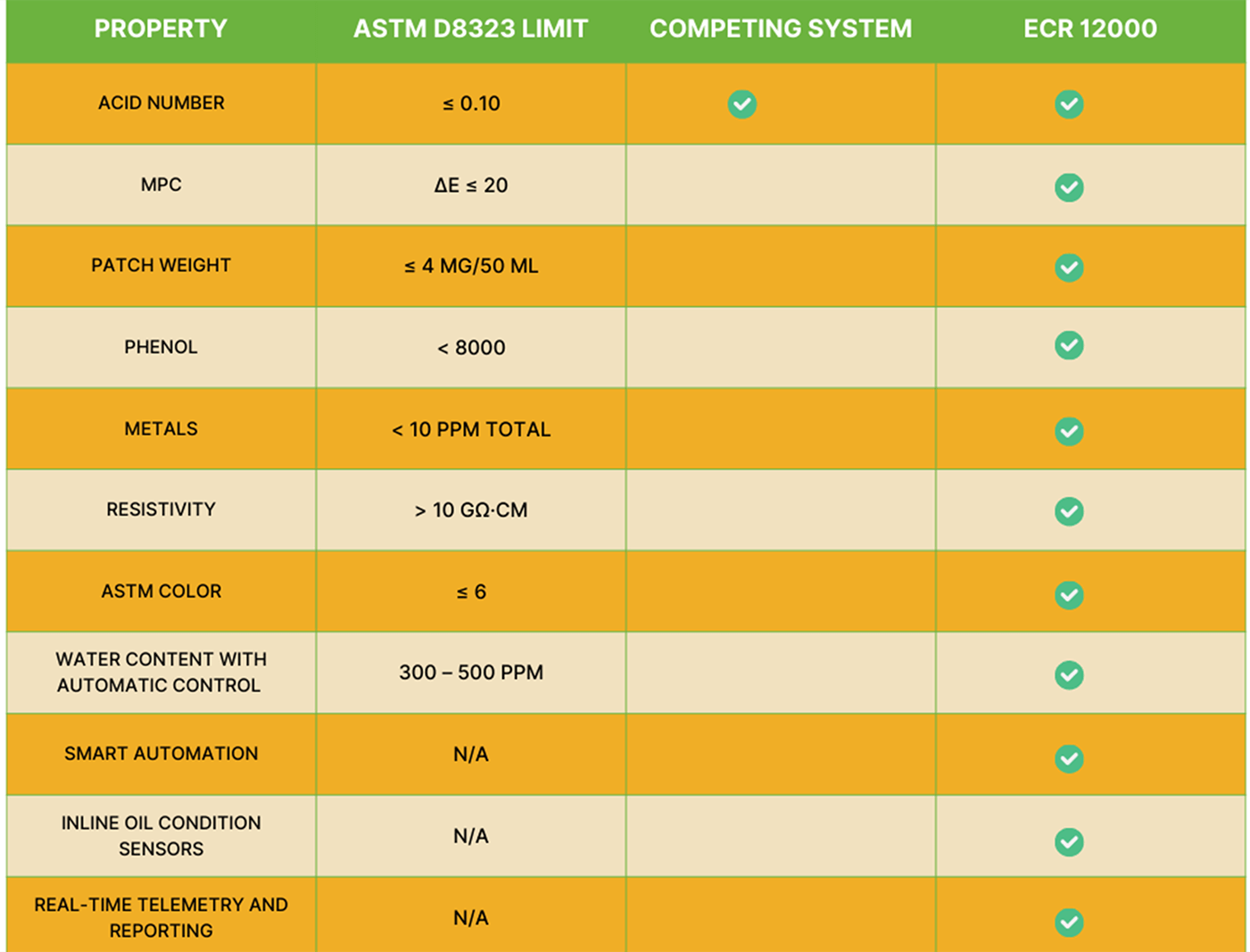

Safeguard Phosphate Ester Fluids from Contamination

Lubricant Chemistry Management is key when it comes to maintaining critical EHC system phosphate ester fluids. Offering a step-change in performance management to ASTM D8323-24 standards, ECR 12000 offers complete fluid management and robust daily reporting, giving you the piece of mind demanded.

From solid contamination, including sub-micron particulate, to resitivity management to comprehensive chemistry management, ECR 12000 is an all-in-one solution integral in the holistic management of phosphate ester fluid quality.

ECR 12000 Features and Benefits:

- Best-in-class performance for acid number and fluid resistivity improvement

- Removes carbon produced from micro dieseling and restores fluid color

- Reduces patch weight by up to 98% or < 4mg / 50ml fluid

- Protects servo valves from mechanical wear

- Reduces total dirt load typically by 75% (by mass) or more

- Decreases air entrainment and increases resistivity

When used as directed and as part of proper fluid maintenance programs, ECR 12000 improves fluid colour, increases resistivity and removes acid and varnish, which is integral in managing phosphate ester fluid quality. Utilizing the benefits of our proven TMR® N2 water removal system, TMR® N2 for water removal, comprehensive fluid chemistry management is achieved, eliminating the need for chemical flushes when maintained over time.

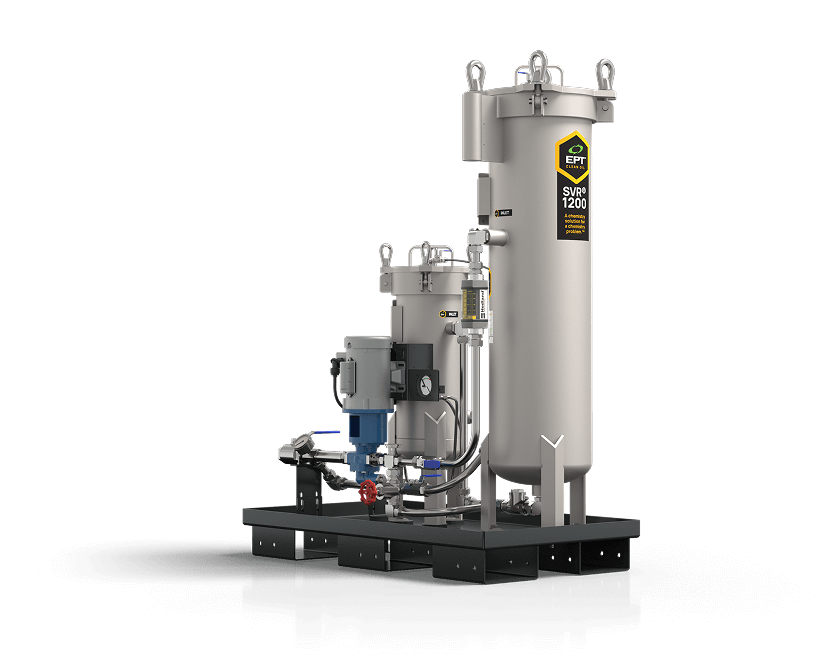

ECR® 10000 Phosphate Ester Conditioning Skid

ECR® 10000 is an integrated skid-mounted kidney loop filtration system designed for phosphate ester fluid, primarily electro-hydraulic control (EHC) applications, equipped with four proprietary filtration technologies to achieve fluid standards as defined in ASTM D8323-24.

The four filtration technologies include:

- ECR Electrostatics

- Patented ICB® ion-exchange

- High-efficiency particulate removal

- TMR® N2 water removal

Phase

1

WATER CONTENT MANAGEMENT

TMR N2 introduces high-purity, dry nitrogen (≥97%) to insulate the reservoir, reducing fluid exposure to oxygen and atmospheric water, thus preventing oxidation and hydrolysis. Continuous operation keeps water content within the ideal range of 200 to 500 ppm.

Phase

2

SUB-MICRON PARTICULATE REMOVAL

ECR Collector elements remove sub-micron particles(<4 microns) that standard filters miss, enhancing fluid life and reducing component wear. ECR Collector media captures contaminants as small as 0.01 microns through advanced electrostatic filtration processes.

Phase

3

DISSOLVED CONTAMINATION REMOVAL

Patented ICB ion-exchange filters eliminate acids and soluble varnish at the molecular level, effectively removing harmful phosphate ester varnish and acids. This enhances EHC fluid stability and significantly extends its lifetime.

Phase

4

FINAL SOLID CONTAMINATION REMOVAL

A high-efficiency particulate filter polishes EHC fluids to ensure their maximum cleanliness.

Meet ECR® 10000

WatchCASE STUDY

In this case study, the ECR 10000 technology was applied in service, delivering substantial benefits to the end user.

BIGGER. BADDER. BOLDER.

In this original debut, we showcase the ECR 10000 and the step change improvement this solution brings to EHC fluids nearest you.

Safeguard Phosphate Ester Fluids from Contamination

Target both categories of solid contamination in phosphate ester fluids with ECR 10000.

>4 micron particulate measured and classified by ISO 11500/4406

<4 micron particulate, which is not measured

Particulate contamination <4 microns, resulting from micro-dieseling (temperature fluid breakdown caused by air release issues), is responsible for fluid darkening. ECR 10000 removes this sub-micron particulate contamination, which is integral in managing phosphate ester fluid quality.

ECR® 10000 Features and Benefits:

- Best-in-class performance for acid number and fluid resistivity improvement

- Removes carbon produced from micro dieseling and restores fluid color

- Reduces patch weight by up to 98% or < 4mg / 50ml fluid

- Protects servo valves from mechanical wear

- Reduces total dirt load typically by 75% (by mass) or more

- Decreases air entrainment and increases resistivity

When used as directed and as part of proper fluid maintenance programs, ECR 10000 improves fluid colour, increases resistivity and removes acid and varnish, which is integral in managing phosphate ester fluid quality. In conjunction with TMR® N2 for water removal, comprehensive fluid chemistry management is achieved, eliminating the need for chemical flushes when maintained over time.

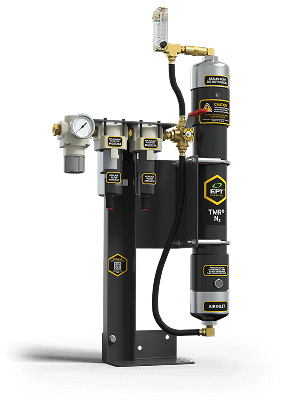

ECR® Collector Elements

ECR Collector elements are designed for ECR electrostatic oil cleaners. ECR Collector elements are not classified as filters as they do not remove particles by their physical size, but rather their weight.The ECR Collector is used to remove sub micron particulates in EHC fluid systems that are below the range of ISO4406.

ECR collectors are the opposite of our patented ICB FRF ion-exchange filters which focus on acid and varnish removal. For complete Lubricant Chemistry Management and to address the contamination equation, ECR Collectors should be used along with ICB FRF ion-exchange filters and our TMR N2 system.

Meet ECR® Collector

WatchMake Informed Decisions with our ACE™ Oil Analysis

At EPT Clean Oil, we specialize in lubricant analysis for critical rotating equipment and EHC systems. We don’t want to be a jack of all trades; our focus is on being the masters of what we do. Each sample that is sent to the Fluid Technical Center is, therefore, examined uniquely.

Our expert chemists drive the advancement of lubricant testing and management through collaboration with industry-leading organizations such as ASTM, STLE, and ICML. We thoroughly review and critically analyze your results before presenting our findings, ensuring precision and reliability. Our commitment is to deliver accurate solutions, always prioritizing quality and providing the insights you need.