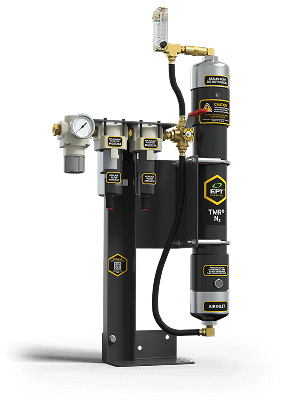

TMR® AquaPurge Coalescer:

Advanced Water Separation & Removal Technology

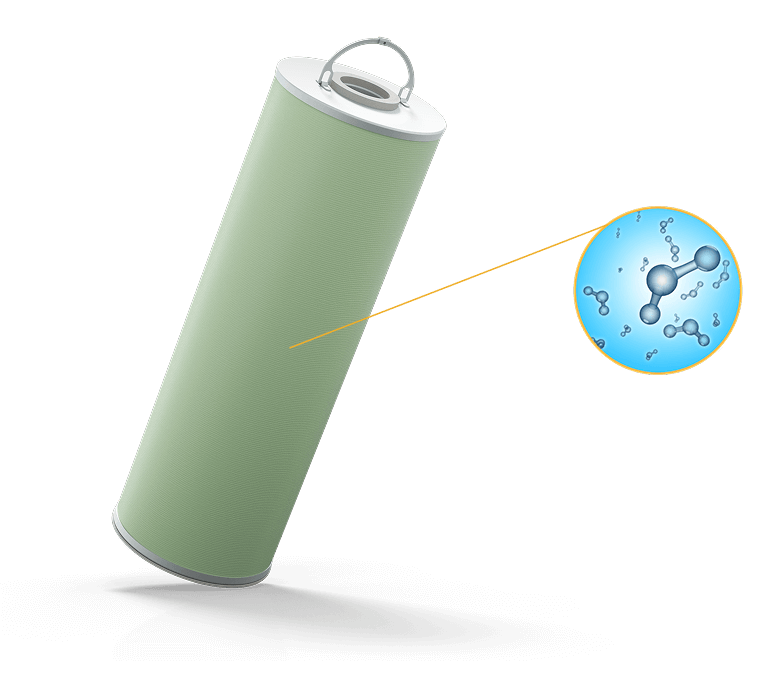

The TMR® AquaPurge Coalescer is an innovative, integrated coalescence and separator technology that rapidly and efficiently removes two forms of water: emulsified and free. Utilizing synthetic hydrophobic membranes to repel water while allowing oil to pass through, this multi-chamber coalescer offers single-pass water-removal efficiencies of up to 90%, allowing for multi-pass water removal to < 200 ppm.

Integrating emulsion-reducing ICB® ion exchange and TMR AquaPurge technologies creates a synergistic effect. ICB ion exchange removes the dissolved contaminants that stabilize oil-water emulsions, and TMR AquaPurge removes the remaining free water and less stable emulsions, enhancing the overall efficiency of water removal in lubricating oil systems.

Meet TMR® AquaPurge Coalescer

Watch- Multi-chamber coalescer offers a proprietary flow path that achieves single-pass water-removal efficiencies of up to 90%, allowing for multi-pass water-removal to < 200 ppm.

- Utilizes synthetic hydrophobic membranes to repel water, while allowing oil to pass through.

- Deliver significant energy savings, using only 15% of the energy required for traditional water removal technologies.

Meet the Ideal Match for TMR® AquaPurge Coalescer

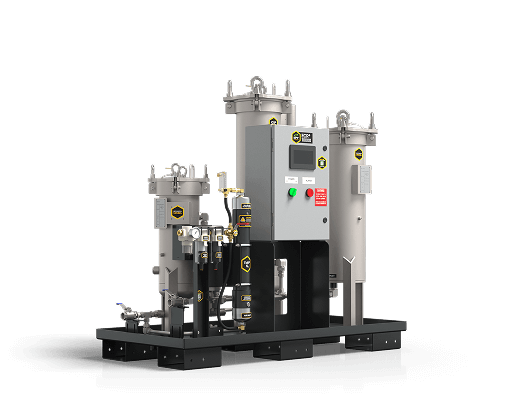

Complete Three-Stage Filtration System for Comprehensive

Lubricant Chemistry Management

The SVR® HYDRO filtration system integrates advanced technologies, including the TMR AquaPurge, to provide a highly effective solution for water removal in lubricating oil systems. This system’s unique multi-stage process ensures superior water separation, enhancing both lubricant quality and operational efficiency.

Together, these technologies create a synergistic effect that enhances water removal, reduces contamination, and improves lubricant quality. The SVR HYDRO system offers a comprehensive solution that ensures optimal performance, reduces maintenance costs, and extends the life of equipment.

Phase

1

Pre-treatment with Patented ICB® Ion-Exchange

The first stage utilizes ICB Ion-Exchange technology, which effectively reduces emulsified water before it even reaches the coalescer. The ion-exchange resins target and remove the dissolved contaminants that stabilize water-oil emulsions. By breaking down these stable emulsions, the ICB process reduces the load on subsequent filtration stages, specifically improving the effectiveness of the TMR® AquaPurge.

Phase

2

Water removal with TMR® AquaPurge Coalesce

The TMR® AquaPurge Coalescer plays a pivotal role as the second phase in the SVR HYDRO system, focusing on the removal of free water and less stable emulsions. After the ion-exchange treatment, the coalescer works to merge and separate water droplets more efficiently, resulting in superior water removal compared to traditional methods.The two-step approach of ICB ion-exchange followed by the TMR® AquaPurge guarantees more thorough water separation, improving the overall performance and longevity of lubricating oil systems.

Meet SVR® HYDRO

WatchMake Informed Decisions with our ACE™ Oil Analysis

At EPT Clean Oil, we specialize in lubricant analysis for critical rotating equipment and EHC systems. We don’t want to be a jack of all trades; our focus is on being the masters of what we do. Each sample that is sent to the Fluid Technical Center is, therefore, examined uniquely.

Our expert chemists drive the advancement of lubricant testing and management through collaboration with industry-leading organizations such as ASTM, STLE, and ICML. We thoroughly review and critically analyze your results before presenting our findings, ensuring precision and reliability. Our commitment is to deliver accurate solutions, always prioritizing quality and providing the insights you need.