Brandon Graf

Brandon Graf, a rotating equipment specialist based in Western Canada, has worked alongside us for over two years, driving measurable improvements in lubricant health and system reliability. Through collaboration and expertise, we’ve seen undeniable results, including bringing oil back into specification in as little as 24 hours. We’re proud to celebrate these successes and look forward to continuing our work together.

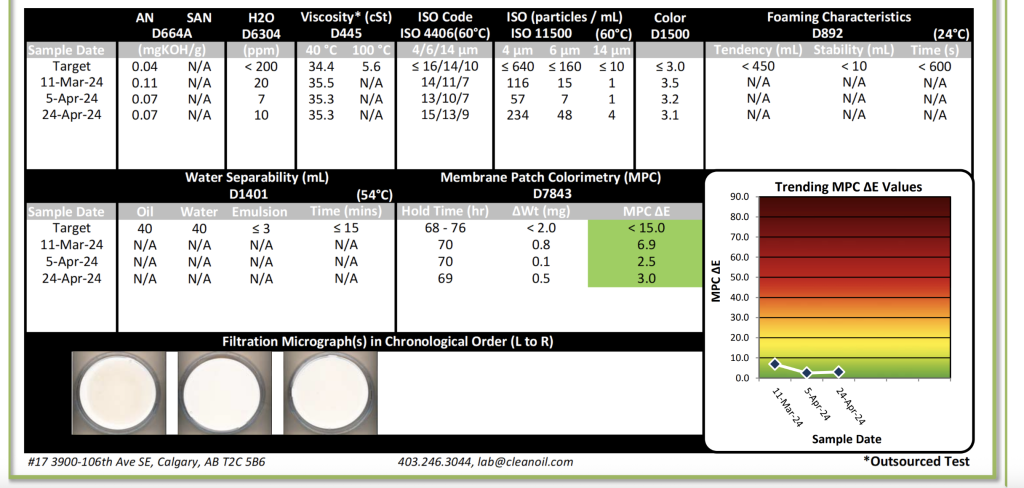

Problem: We were beginning to run into some varnishing issues on two T130 Solar units and provided our most recent oil analysis as well as the Solar specification to EPT Clean Oil’s Fluid Technical Center team. Based on the analysis, we were beginning to deviate from the Solar specifications and recommendations for the T130.

- Oil reservoir; 68 – 80 C (At 26C ambient, the reservoir climbs to 80 C)

- Oil header; 51 – 63 C

- Cooler Delta T; 15 – 20 C (Efficiency on cooler delta lower with ambient increase)

Critical to the facility as the units supply both the entirety of power requirements for the plant and heating for the plants, both systems had elevated risk of varnish-related problems. The reported oil temperatures (68 – 80 C) are also on the high side, which may be indicative of varnish already being a problem at this site. This could be from varnish deposits leading to increased friction, or varnish deposits leading to reduced cooler delta Ts.

Fluid Technical Center Review

- MPC results from both systems indicated that varnish has been present for some time and are near or above Solar’s in-service limit. This may account for the systems’ relatively high operating temperatures. It also places these units at heightened risk of varnish-related failure.

- Although both oils’ acid numbers were well within Solar’s 0.60 max AN limit, this limit is not a good threshold for Petro-Canada TurboFLO XL 32. Both fluids have had acid levels that can lead to varnishing with this oil for some time.

- The oil had elevated particle levels, suggesting that this system’s filters are not performing adequately. Even if these filters are replaced, they will be unable to remove varnish since it tends to be dissolved under operating conditions.

- RPVOT testing revealed that these oils have 67 – 75% of their life left. They could therefore be reliably used for many more years if the observed breakdown (varnish, acids) and contaminant (sodium, particles) levels are addressed through appropriate conditioning.

Solution: Based on previous experience with T130 turbines and Petro-Canada TurboFLO XL 32, the fluid was an excellent candidate for remediation with an SVR® conditioning system. We recommended installation of an SVR service unit as soon as possible to return the oil to specification quickly. SVR quickly restores the lubricant to an unsaturated state which makes the lubricant behave like a solvent where it will remove any deposits it comes into contact with. Because the oil will be maintained continuously, varnish will be removed and dissolved into, and then removed from the oil with SVR in a positive feedback type loop.

Results: After implementing the SVR varnish removal system, the acid number decreased from 0.11 in March to 0.07 in April. The MPC AE value also fell within the acceptable range of less than 15. This indicates a relatively low level of degradation products in the fluid and the filter micrographs further support this observation.

Through collaboration and expertise, we’ve seen undeniable results, including bringing oil back into specification in as little as 24 hours.