Lubricant Chemistry Management Solutions

ICB®

ION-EXCHANGE FILTERS

ICB® filters are industry leading patented ion exchange filters that offer unmatched performance in the removal of acids, varnish and dissolved oxidation molecules.

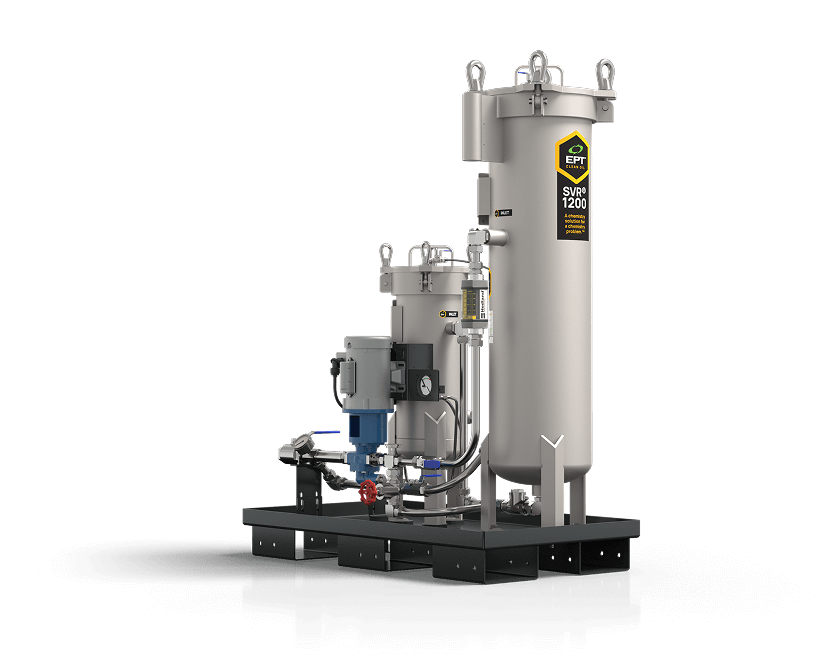

SVR®

LUBRICANT CONDITIONING SYSTEM

SVR® utilizes patented ICB® ion-exchange filters to permanently remove dissolved breakdown products and prevent harmful varnish deposits from forming.

ECR® Collector

Sub-micron Particulate Removal

ECR® Collector elements are designed for ECR electrostatic oil cleaners, offering an effective EHC filtration solution that targets sub-micron particulate removal.

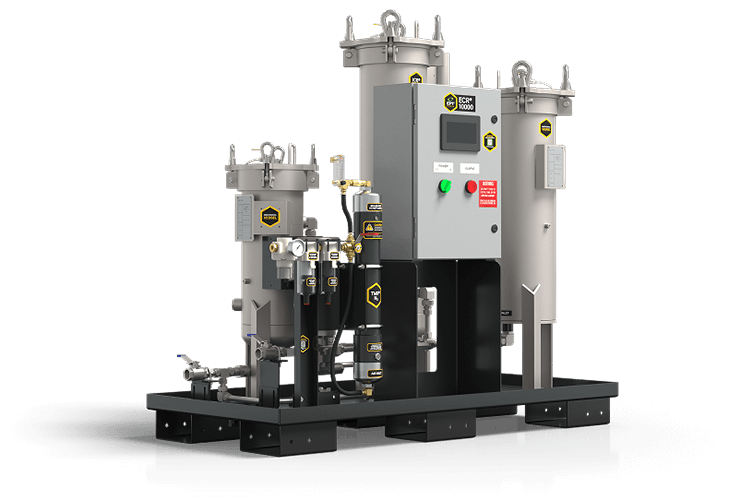

ECR®

Phosphate Ester Conditioning Skid

ECR® 10000 is an industry-leading complete phosphate ester conditioning skid that targets ultra-fine solids and dissolved contaminants in critical EHC applications.

TMR® AquaPurge Coalescer

Coalescence & Separator Element

TMR® AquaPurge Coalescer is an integrated coalescence and separator technology that rapidly and efficiently removes two forms of water: emulsified and free.

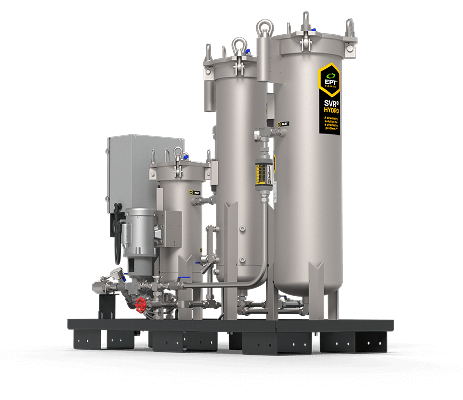

SVR® HYDRO

WATER SEPARATION AND REMOVAL

SVR® HYDRO offers absorption of soluble contamination, microfiltration of insoluble contaminants, and mechanical coalescing, addressing free and emulsified water.

Fluid Technical Center

Specialized Oil Analysis & Evaluation

Our testing packages provide in-depth evaluations and root cause analysis specific to your application, with final recommendations in our ACE™ report.

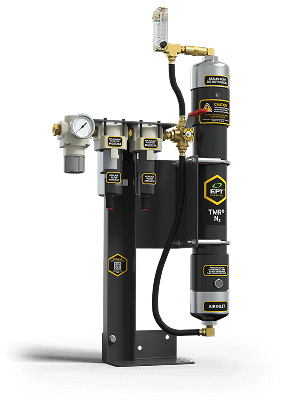

TMR® N2

WATER REMOVAL

TMR® N2 is a highly effective, low-cost, nitrogen blanketing system that provides unlimited capacity to remove water and eliminate atmospheric water ingression.