Determine The Propensity Of A Lubricant To Form Varnish Deposits

Lubricant varnish potential testing is an essential part of turbine and compressor lubricant management. For rapid assessment of potential varnish-related problems on-site use ASTM D7843 approved MPC varnish test. For all critical turbine installations, monthly MPC testing is recommended to mitigate catastrophic varnish-related failures.

MPC Varnish Test Features and Benefits:

- High-quality, laboratory-grade equipment

- Includes all materials and consumables required to prepare the patch used for measuring MPC varnish

- Simple to use, with step-by-step instructions and video demonstration (see below)

Access to our expert chemistry team is included with the purchase of our MPC varnish potential testing products.

Our chemistry team has completed 1000’s of MPC varnish potential tests. From answering a quick question to in-depth technical support, we offer invaluable access to experts for all aspects of MPC testing.

How Does the MPC Varnish Test Work?

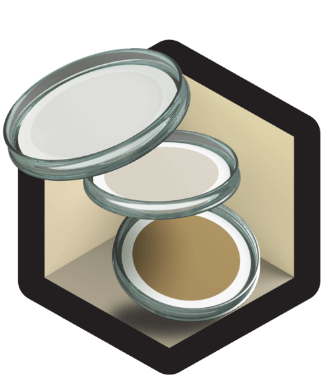

Colored varnish precursors accumulate from normal oil breakdown. These can be measured by MPC testing.

- Mix the oil with a solvent to convert dissolved varnish precursors into solids, trapped on a filter patch.

- Scan the patch using a spectrophotometer to provide an MPC value.

- MPC values over 15 require further attention.

The higher the MPC value, the higher the amount of varnish deposits and precursors dissolved in the lubricant and the greater the propensity for the lubricant to form harmful varnish deposits.

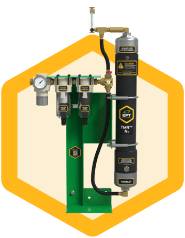

MPC Varnish Potential Test Kits

There are three primary components to the MPC varnish potential test:

- Patch test kit apparatus

- Vacuum pump

- Spectrophotometer

We offer MPC test kit options and one type of spectrophotometer.